Premium Valve Stuffing Box ODM Supplier | Quality Solutions & Factory Manufacturing

At Sichuan Yining Machinery Equipment Co., Ltd., we provide high-quality Valve Stuffing Boxes specifically designed for OEMs, factories, and manufacturers. Our commitment to precision and durability ensures that our products meet the rigorous demands of your operations. With extensive industry experience, we recognize the critical role reliable sealing solutions play across various applications. Our versatile Valve Stuffing Boxes are engineered to deliver optimal performance, providing long-lasting reliability while minimizing maintenance expenses. We excel in customizing solutions to align with your specific requirements, positioning us as a preferred partner for businesses aiming to enhance operational efficiency. When you choose our products, you receive an unwavering commitment to quality and service, dedicated to your success. Your satisfaction remains our top priority!Best Methods To Valve Stuffing Box Dominates From Concept to Delivery

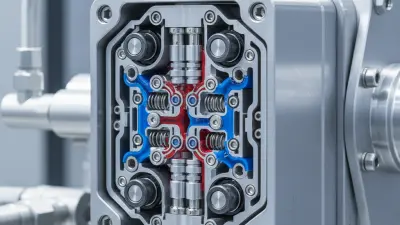

At Sichuan Yining Machinery Equipment Co., Ltd., we understand that the valve stuffing box is a critical component in ensuring the efficiency and reliability of various industrial processes. Established in 2005, our company has dedicated itself to the processing and production of diverse valve fittings, leveraging our technical team's rich theoretical knowledge and practical experience. From the initial concept to the final delivery, our best methods for designing and manufacturing valve stuffing boxes focus on precision, quality, and customer satisfaction.

Our approach begins with comprehensive research and analysis to craft innovative designs that meet the specific needs of our clients. We utilize advanced materials and cutting-edge manufacturing techniques to ensure the durability and performance of our valve stuffing boxes. Throughout the production process, stringent quality control measures are implemented, guaranteeing that each product not only meets but exceeds industry standards. Our commitment to quality is further reinforced by our extensive management and production experience, enabling us to deliver reliable solutions tailored to the unique requirements of various industries.

For global buyers seeking dependable valve fittings, partnering with Sichuan Yining Machinery Equipment Co., Ltd. means accessing top-tier products backed by a dedicated team committed to excellence. Let us help you enhance your operations with our expertly crafted valve stuffing boxes that promise to dominate the market from concept to delivery, ensuring optimal performance and longevity in even the most demanding applications.

Best Methods To Valve Stuffing Box Dominates From Concept to Delivery

| Method | Description | Advantages | Challenges | Applicability |

|---|---|---|---|---|

| Sealing Material Selection | Choosing appropriate sealing materials for specific applications. | Improved leak prevention and durability. | Cost of high-performance materials. | Oil and gas, chemical processing. |

| Regular Maintenance | Scheduled checks and servicing of stuffing boxes. | Increased lifespan of valves. | Requires time and resources. | All industries using valves. |

| Advanced Design Techniques | Utilizing CAD and simulation tools for design optimization. | Enhanced performance and reliability. | Requires skilled personnel and software investment. | High-tech industries, manufacturing. |

| Training for Operators | Educating staff on best practices for valve operation. | Reduced errors and safety incidents. | Initial time investment for training. | All operational settings. |

| Technological Integration | Incorporating IoT and smart technologies for monitoring. | Real-time data for proactive maintenance. | High upfront costs and complexity. | Industries with high uptime requirements. |

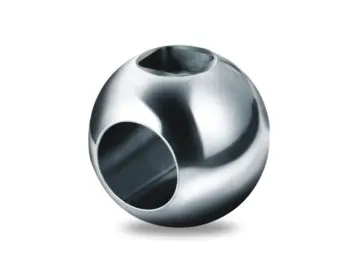

Uncovering Valve Stuffing Box Manufacturer Products

S

Samantha Bennett

Exceptional product and service quality! The after-sales team is quite professional.

07

June

2025

K

Kayla Rogers

The product quality is top-notch! Support staff went above and beyond in their service.

22

June

2025

O

Owen Roberts

Great purchase! The knowledgeable support team made the experience even better.

05

June

2025

R

Riley Green

Fantastic quality, and the service provided afterwards was simply superb.

04

July

2025

A

Angela Clark

Amazing product! The after-sales service team was incredibly helpful and engaged.

19

June

2025

N

Nora Adams

Delightful experience! Great product quality and equally great customer service.

05

June

2025