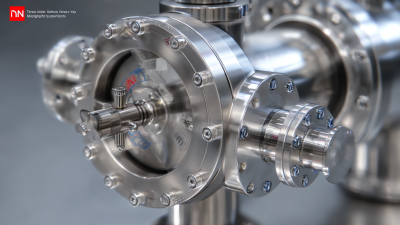

High-Quality Valve Seat Side ODM Factory for Engine Components Supply

Our high-quality valve seat sides are engineered to meet the stringent requirements of OEMs and manufacturing facilities. With years of experience, we prioritize precision and durability, ensuring that each product adheres to rigorous industry standards. Each valve seat side is meticulously crafted for optimal performance, making them a reliable choice for a variety of applications in your machinery. Trust in our expertise to deliver the quality and reliability you need.Methods To Choose Valve Seat Side Factory Products

When selecting valve seat side factory products, global buyers must consider a variety of factors to ensure they are making the best decision for their operations. Established in 2005, Sichuan Yining Machinery Equipment Co., Ltd. has specialized in the processing and production of a wide range of valve fittings, making us a trusted source in the industry. One key method is to assess the quality of materials used in valve seat production. High-grade materials not only enhance durability but also contribute to overall performance efficiency.

Another important aspect is evaluating the manufacturer's technical team. Our skilled professionals at Sichuan Yining boast extensive theoretical knowledge matched with practical experience, ensuring that our products meet international standards and customer specifications. Additionally, consider the manufacturer's track record and production capabilities. An established company that has amassed rich management and production experience, like Sichuan Yining, can offer tailored solutions and reliable service, which is crucial for global procurement needs. Ultimately, choosing the right valve seat products involves a strategic approach that values quality, expertise, and proven reliability.

Methods To Choose Valve Seat Side Factory Products

| Criteria | Description | Importance Rating (1-5) | Recommended Actions |

|---|---|---|---|

| Material Quality | Evaluate the durability and strength of the materials used in valve seat products. | 5 | Choose manufacturers who provide material certifications. |

| Manufacturing Process | Understand the fabrication techniques employed to ensure product precision. | 4 | Look for CNC machining and quality inspections in the process. |

| Industry Standards | Check if the products comply with international standards (e.g., ISO). | 5 | Request documentation of compliance from suppliers. |

| Technical Support | Assess the availability of technical assistance or consultancy. | 3 | Prioritize suppliers offering ongoing support and expertise. |

| Cost-effectiveness | Evaluate pricing relative to quality and features, ensuring value. | 4 | Compare multiple suppliers to find the best value. |

| Delivery Time | Consider the lead time for receiving products, affecting project schedules. | 3 | Inquire about production and shipping timelines before ordering. |

Why Choose Valve Seat Side Factory Manufacturer

H

Henry Martinez

I love this product! The after-sales staff provided a level of service that was truly professional.

03

July

2025

M

Megan Ward

I am extremely satisfied! The customer service team was not only professional but genuinely caring.

17

May

2025

K

Kayla Rogers

The product quality is top-notch! Support staff went above and beyond in their service.

22

June

2025

E

Evelyn Brown

Top-notch quality! The support team was thorough and very helpful.

23

June

2025

S

Sienna Morris

I am thoroughly impressed! The product quality and proactive support made my day.

26

June

2025

D

Dominic Parker

What a wonderful experience! The product quality is commendable and matched by outstanding support.

21

June

2025