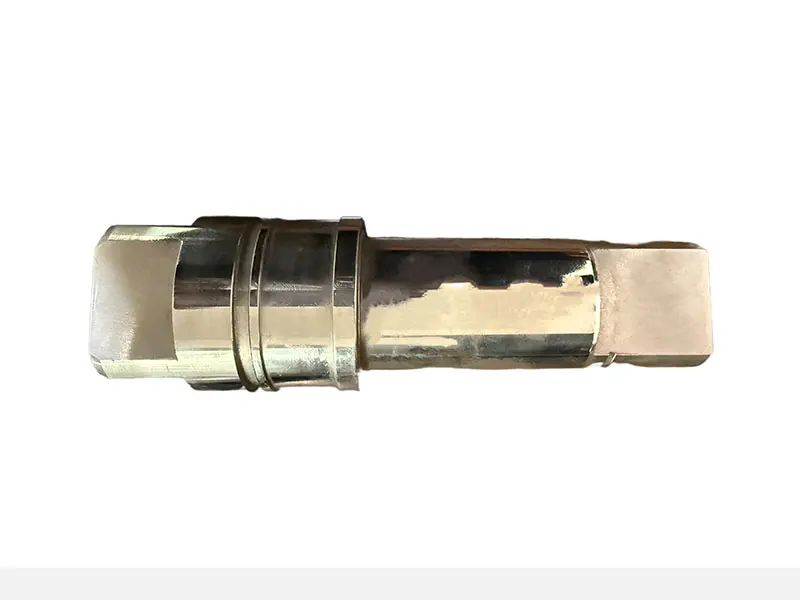

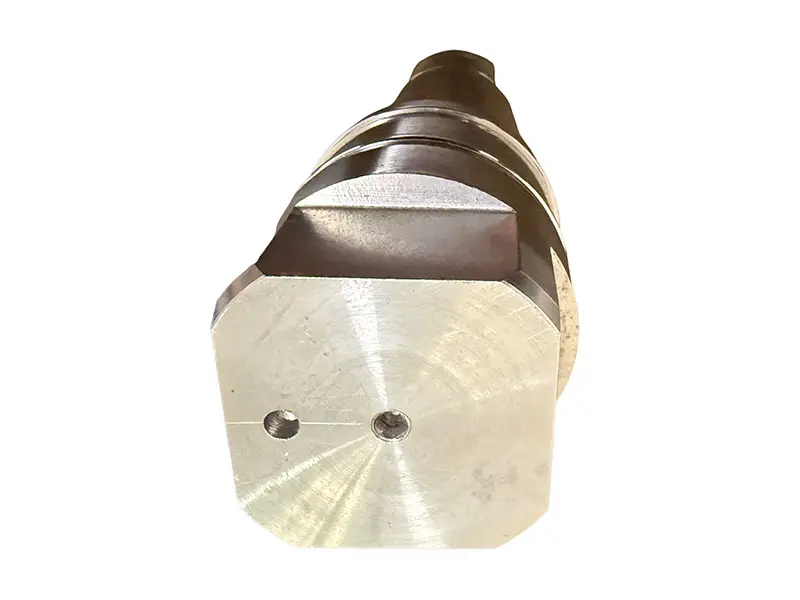

Stainless Valve Stem for Ball Valves

-

Design & Production

The upper section of the stem fits the actuator drive, while the lower end engages precisely with the ball slot. Our machining process focuses on tight tolerances, smooth surface finish, and stable torque performance.

Main production steps include:

• CNC turning, milling, and threading

• Precision grinding and polishing

• Heat treatment for 17-4PH types

• Passivation or nickel plating for extra corrosion protection

• 100% inspection for dimensions and surface quality

Every stainless valve stem is tested for hardness, runout, and surface finish before packing.

-

Technical Specifications

-

Key Advantages

-

Applications

-

Quality Control

-

FAQ