Top Single Plate Wafer Check Valve Manufacturer for Maximum Efficiency

As a leading provider of high-quality valve solutions, we recognize the essential role that single plate wafer type check valves play in various industrial applications. Our valves are meticulously designed to ensure optimal flow control, effectively preventing backflow while maintaining operational efficiency. With extensive expertise in manufacturing, we are dedicated to delivering products that adhere to stringent industry standards. Our check valves are durable, cost-effective, and designed for easy installation and maintenance, making them ideal for sectors such as oil and gas, water treatment, and manufacturing. At Sichuan Yining Machinery Equipment Co., Ltd., we are committed to outstanding customer service and support, collaborating to provide tailored solutions that enhance your operational efficiency.Best Practices For Single Plate Wafer Type Check Valve Manufacturer From Concept to Delivery Ahead of the Curve

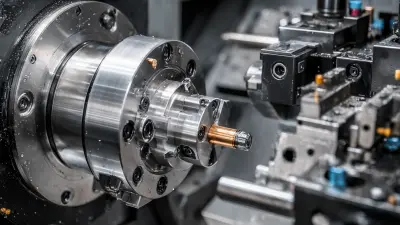

In the competitive landscape of valve manufacturing, single plate wafer type check valves have emerged as a pivotal solution for efficient fluid management. For procurement professionals, understanding the best practices in selecting a manufacturer is essential to ensure product reliability and performance. One key aspect is the emphasis on a robust design that caters to specific application needs. Engaging with a manufacturer who demonstrates deep technical knowledge and has hands-on experience in valve engineering can lead to superior product outcomes.

Additionally, the manufacturer's commitment to quality control throughout the production process significantly affects product durability and functionality. It is crucial to partner with a company that implements stringent testing protocols and adheres to international standards, thereby assuring buyers of the consistency and safety of their products. Collaborating with a manufacturer that embraces innovation and incorporates advanced technologies can also provide procurement teams with a competitive edge, enabling them to stay ahead of market demands.

Finally, timely delivery and effective communication are vital in the supply chain. A proficient manufacturer prioritizes timely order fulfillment while maintaining transparency throughout the production cycle. This not only alleviates procurement concerns but also fosters long-term relationships built on trust and reliability. By following these best practices, global buyers can make informed decisions and secure high-quality single plate wafer type check valves that meet their operational requirements.

Best Practices For Single Plate Wafer Type Check Valve Manufacturer From Concept to Delivery Ahead of the Curve

| Dimension | Specification | Material | Testing Standards | Delivery Time |

|---|---|---|---|---|

| 2 inches | API 594 | Ductile Iron | ISO 5208 | 4 weeks |

| 3 inches | ANSI B16.34 | Carbon Steel | API 598 | 5 weeks |

| 4 inches | ASME B16.10 | Stainless Steel | API 598 | 6 weeks |

| 6 inches | ANSI B16.5 | Brass | ISO 5208 | 7 weeks |

| 8 inches | API 600 | Alloy Steel | API 598 | 8 weeks |

7 Key Tips To Single Plate Wafer Type Check Valve Manufacturer Where Service Meets Innovation Industry Giant

M

Michael Thompson

The quality of the product exceeded my expectations. The team has been incredibly supportive throughout the entire purchasing process.

02

June

2025

S

Sophia Williams

I am thoroughly impressed with the customer service. Every query I had was addressed promptly and professionally.

10

June

2025

J

Jackson Gray

Quality is superb! The support staff were knowledgeable and very responsive to my needs.

01

June

2025

L

Landon Turner

Impressive craftsmanship! The response time from the support team was remarkably fast.

02

July

2025

A

Alyssa Hill

I love this product! The ongoing support reflected a dedication to customer satisfaction.

19

June

2025

M

Mila Allen

Exceptional quality of product! Their customer service was proactive and very friendly.

06

July

2025