Shaft Connection Types: ODM Solutions from Leading Manufacturers and Factories

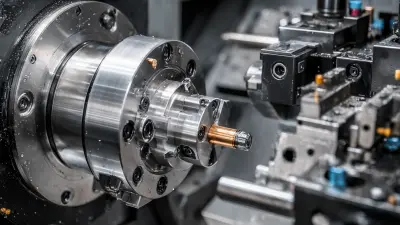

At Sichuan Yining Machinery Equipment Co., Ltd., we understand the essential role that high-quality shaft connection types play in the efficiency and reliability of your machinery. As an OEM supplier, we offer a wide range of options tailored to various industrial applications. Our products include both flexible couplings and rigid connections, ensuring that you can easily find the ideal solution for your needs. Our factory is dedicated to manufacturing durable components that not only meet but exceed performance expectations. With a focus on customized solutions, we aim to partner with you to enhance operational efficiency and reliability in your projects. Trust us to provide the quality and reliability that your machinery deserves.Why Consider Shaft Connection Types Application Guarantees Peak Performance

When selecting machinery components, understanding the various types of shaft connections is critical to ensure optimal performance and reliability. At Sichuan Yining Machinery Equipment Co., Ltd., we recognize the importance of this choice, as it directly impacts the efficiency and functionality of valve fittings. Established in 2005, our company specializes in producing high-quality valve fittings, supported by a technical team with extensive theoretical knowledge and practical experience.

The selection of appropriate shaft connection types can guarantee that machinery operates at peak performance, minimizing downtime and maintenance costs. Factors to consider include the specific application demands, the material compatibility, and the required torque transmission. By engaging with industry experts and leveraging years of production experience, we assist global procurement professionals in making informed decisions regarding shaft connections. Our dedication to quality and performance enables us to provide tailored solutions to meet diverse global industry needs.

In a market where efficiency and reliability are paramount, understanding the implications of shaft connection choices can be a game-changer. Sichuan Yining Machinery Equipment Co., Ltd. is committed to not only delivering superior valve fittings but also ensuring that our clients fully understand the application guarantees of our products. Partnering with us means choosing quality, expertise, and peak performance for your machinery applications.

Why Consider Shaft Connection Types Application Guarantees Peak Performance

| Connection Type | Application | Advantages | Disadvantages | Peak Performance Guarantee |

|---|---|---|---|---|

| Keyed Connection | Industrial Machinery | High torque transmission | Potential for misalignment | Yes |

| Splined Connection | Automotive Driveshafts | Enhanced torque handling | Complex manufacturing | Yes |

| Bolted Connection | Construction Equipment | Ease of assembly and disassembly | Bolts may loosen over time | Yes |

| Welded Connection | Heavy Machinery | High strength and rigidity | Difficult to disassemble | Yes |

| Coupling Connection | Robotics | Flexibility in alignment | May require regular maintenance | Yes |

How To Find The Best Shaft Connection Types Pioneers in the Field in 2025

A

Ava Hall

Excellent product! I was especially impressed by the thoroughness and friendliness of the after-sales service.

08

May

2025

O

Oliver Turner

What an excellent product! The after-sales service provided was thorough and professional.

05

July

2025

E

Elijah Murphy

High quality and great performance! The support staff was engaging and very helpful.

05

June

2025

C

Caleb Carter

High quality with excellent support! The staff were genuinely eager to help.

19

June

2025

L

Lydia Sanchez

What a great experience! The after-sales team has been invaluable in addressing my needs.

31

May

2025

E

Ella Turner

Top-notch experience! The product quality and customer service were outstanding.

23

June

2025