OEM Solutions for Rigid Shaft Couplings with Keyway for Factories and Manufacturers

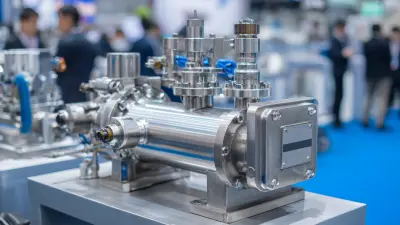

Rigid shaft coupling keyways are essential for maintaining the efficiency and performance of machinery. At Sichuan Yining Machinery Equipment Co., Ltd., we offer top-quality keyway solutions designed to meet the diverse needs of various industries. Our products ensure a robust connection between shafts, enhancing both the durability and reliability of your equipment. With a focus on easy installation and maintenance, our rigid shaft coupling keyways are an excellent choice for professionals who demand high performance. Whether you are building new machinery or servicing existing systems, our expertise and commitment to quality guarantee the perfect coupling keyway solution for your needs. Optimize your machinery's functionality with our trusted solutions.

How To Select Rigid Shaft Coupling Keyway Pioneers in the Field Supplies the World’s Top Brands

Selecting the right rigid shaft coupling keyway is crucial for ensuring the reliability and efficiency of mechanical systems. When it comes to sourcing top-quality components, understanding the intricacies of keyway specifications and their manufacturing processes can significantly impact your decision. A well-designed keyway not only facilitates secure connections between shafts but also minimizes wear and tear, ultimately extending the lifespan of your machinery. Therefore, buyers must pay close attention to the technical specifications and materials used in the production of these couplings.

In today's global market, the demand for robust and dependable shaft couplings has surged, compelling manufacturers to adopt innovative technologies and techniques. A solid technical background, paired with extensive experience in processing and production, enables engineers to develop couplings tailored to meet diverse industrial needs. When evaluating potential suppliers, consider their knowledge base, production capabilities, and commitment to quality assurance. Partnering with industry leaders who prioritize precision engineering and rigorous testing can provide significant advantages, ensuring you procure components that align with the operational demands of your machinery.

Supply chain dynamics and international standards play a significant role in the procurement process. As you explore options, ensure that your chosen supplier has a comprehensive understanding of global market trends and complies with international regulations. Collaborating with companies deeply rooted in manufacturing valve fittings can also provide insights into complementary products, streamlining your sourcing experience. By making informed decisions and prioritizing reliable partnerships, you can enhance your operational efficiency and maintain a competitive edge in your industry.

How To Select Rigid Shaft Coupling Keyway Pioneers in the Field Supplies the World’s Top Brands

| Type | Material | Dimension (mm) | Max Torque (Nm) | Keyway Size (mm) |

|---|---|---|---|---|

| Rigid Coupling A | Aluminum | 50 x 30 | 200 | 10 |

| Rigid Coupling B | Steel | 60 x 40 | 350 | 12 |

| Rigid Coupling C | Cast Iron | 80 x 50 | 500 | 15 |

| Rigid Coupling D | Stainless Steel | 90 x 60 | 600 | 16 |

Why Invest In Rigid Shaft Coupling Keyway Supplier in 2025

A

Ava Hall

Excellent product! I was especially impressed by the thoroughness and friendliness of the after-sales service.

08

May

2025

H

Henry Martinez

I love this product! The after-sales staff provided a level of service that was truly professional.

03

July

2025

A

Aiden Scott

The quality is impressive! Customer support was friendly and extremely knowledgeable.

09

June

2025

D

David Walker

I’ve purchased many similar products, but this one stands out! Great after-sales service.

02

July

2025

E

Ella Turner

Top-notch experience! The product quality and customer service were outstanding.

23

June

2025

D

Dominic Parker

What a wonderful experience! The product quality is commendable and matched by outstanding support.

21

June

2025