ODM Quick Disconnect Shaft Coupling - Reliable Suppliers & Quality Factories

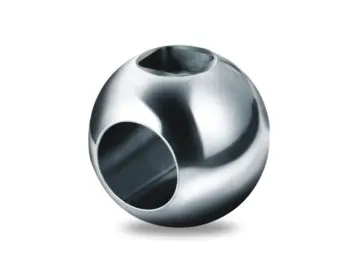

Our Quick Disconnect Shaft Coupling is engineered for reliability and optimal performance, providing seamless connections for efficient power transmission in your machinery. As a trusted ODM supplier and manufacturer, we prioritize quality and usability to enhance your operational efficiency. Manufactured under stringent quality controls at Sichuan Yining Machinery Equipment Co., Ltd., this coupling guarantees durability and consistent performance, meeting all your technical requirements.

Insider Tips For Quick Disconnect Shaft Coupling Service Global Reach

When it comes to maintaining the efficiency of your machinery, understanding the intricacies of quick disconnect shaft coupling service is essential. These components play a pivotal role in connecting two rotating shafts while allowing for easy assembly and disassembly. For global buyers, recognizing the nuances of their service can lead to significant savings in time and maintenance costs. Here are some insider tips to ensure optimal performance and longevity of these coupling systems.

Regular inspection is key. It’s advisable to check for wear and tear, misalignment, and any signs of corrosion. Attention to the coupling's lubricating system is also crucial, as proper lubrication reduces friction and heat buildup, ultimately extending the life of the coupling. Moreover, having trained personnel who understand the assembly and disassembly process can mitigate the risk of damage during service. Access to quality spare parts is essential; sourcing from reputable manufacturers guarantees reliability and performance.

Understanding the specific requirements of your application is vital. Different industries may demand varying specifications from their couplings, influenced by factors such as load capacity and environmental conditions. Engaging with knowledgeable suppliers who offer tailored solutions can greatly enhance efficiency. The global market is rich with options, and making informed decisions based on accurate information will equip you to maintain optimal operational standards while reducing downtime.

Insider Tips For Quick Disconnect Shaft Coupling Service Global Reach

| Tip Category | Service Tip | Best Practice |

|---|---|---|

| Maintenance | Regular inspection of coupling alignment | Check every 500 hours of operation |

| Replacement | Use original equipment manufacturer parts when available | Minimize risks of failure and extend life |

| Lubrication | Apply appropriate lubrication methods based on usage | Consult the coupling manual for specifications |

| Testing | Conduct regular performance tests on couplings | Schedule every 1000 hours to detect issues early |

| Training | Ensure staff are trained in disconnect coupling operations | Regularly update training materials and sessions |

| Documentation | Keep records of all maintenance and service work | Use digital logs for easier access and tracking |

The Ultimate Guide to Quick Disconnect Shaft Coupling in 2025 Service Backed by Expertise

A

Ava Hall

Excellent product! I was especially impressed by the thoroughness and friendliness of the after-sales service.

08

May

2025

S

Serena Lee

Amazing product! The commitment to after-sales service really struck me.

22

May

2025

H

Hailey Cooper

The quality is outstanding! I was particularly impressed by the knowledgeable support staff.

02

June

2025

D

David Walker

I’ve purchased many similar products, but this one stands out! Great after-sales service.

02

July

2025

S

Sophie Lee

Absolutely an amazing product! The after-sales team was knowledgeable and responsive.

21

June

2025

G

Gavin Wright

Superb experience! The commitment to quality shines through, both in the product and the service.

22

May

2025