Best Suppliers of Precision Machined Components for Your Manufacturing Needs

As a specialist in precision machined components, I recognize the essential role these parts hold in your operations. My commitment is to deliver high-quality, customizable solutions designed specifically for your requirements. With a focus on durability, accuracy, and performance, each component adheres to strict standards. At Sichuan Yining Machinery Equipment Co., Ltd., we provide a wide variety of precision components suitable for diverse industries, including automotive and aerospace. I am dedicated to guiding you in selecting the optimal components to meet your project needs. You can rely on us for timely deliveries and competitive pricing. My goal is to establish strong partnerships to enhance your supply chain efficiency and support your production objectives with precision-engineered solutions that deliver results. Your success is my priority, and I aim to simplify your sourcing process.Practical Strategies for Precision Machined Components Suppliers Ahead of the Curve Where Service Meets Innovation

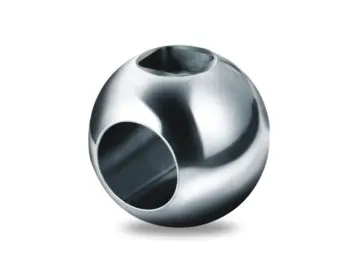

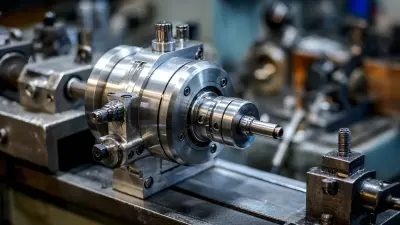

In the fast-evolving world of precision machined components, suppliers must stay ahead of the curve by embracing innovative strategies that enhance service delivery. One effective approach is to leverage technology for improved manufacturing processes, ensuring higher accuracy and efficiency in producing valve fittings. Implementing advanced machinery and software solutions can streamline operations, reduce lead times, and minimize errors, ultimately leading to cost savings and increased customer satisfaction.

Additionally, fostering strong communication with clients can significantly enhance service quality. Understanding the specific needs and challenges faced by global purchasers allows suppliers to tailor their offerings accordingly. Regular feedback loops can help in refining products and services, ensuring they meet market demands. Furthermore, investing in training and development for the technical team not only enhances their skill set but also positions the company as an industry leader capable of delivering innovative solutions that address emerging trends and customer expectations.

Finally, establishing strategic partnerships with other industry players can open new avenues for collaboration and growth. By sharing knowledge and resources, suppliers can enhance their product offerings and penetrate new markets more effectively. As the landscape of precision machining continues to evolve, those who prioritize innovation and exceptional service will be well-positioned to thrive in the competitive global marketplace.

Practical Strategies for Precision Machined Components Suppliers Ahead of the Curve Where Service Meets Innovation

| Strategy | Description | Benefits | Implementation Timeframe |

|---|---|---|---|

| Adoption of Advanced CNC Technology | Investing in the latest CNC machines to enhance precision and capabilities. | Improved product precision and reduced lead times. | 6-12 months |

| Implementing Lean Manufacturing | Streamlining operations to reduce waste and enhance efficiency. | Cost savings and faster production times. | 3-6 months |

| Collaboration with R&D Teams | Working closely with research and development to innovate new products. | Enhanced product offerings and meeting customer needs. | Ongoing |

| Investing in Employee Training | Providing training programs for employees to enhance skills. | Higher quality work and increased employee satisfaction. | 1-3 months |

| Customization and Flexibility | Offering customized components based on client specifications. | Increased customer loyalty and higher orders. | 2-4 months |

How To Precision Machined Components Suppliers More Than a Supplier - A Partner Your Trusted OEM Partner

E

Ella Mitchell

What a delight! The quality stands out, and the customer support was exceptional.

21

May

2025

B

Benjamin Phillips

The product is fantastic, and I appreciate the dedicated follow-up from the customer service team.

01

July

2025

R

Riley Green

Fantastic quality, and the service provided afterwards was simply superb.

04

July

2025

D

Daniel Harris

I am truly impressed! The level of care taken by the customer service team was exceptional.

10

May

2025

H

Hunter Reed

Fantastic product! Their dedication to customer service is clear and impactful.

31

May

2025

C

Clara Evans

Absolute joy to use this product! Thankful for the attentive after-sales service.

01

June

2025