Top ODM Suppliers & Factories for Misaligned Shaft Couplings - Quality & Reliability

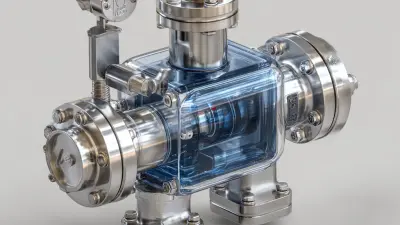

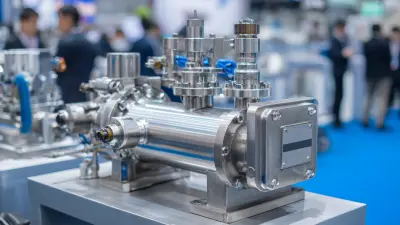

Achieving efficient machinery operation relies heavily on selecting the right Misaligned Shaft Coupling. Sichuan Yining Machinery Equipment Co., Ltd. specializes in high-quality couplings tailored for OEM needs and industrial applications. Our products are engineered to minimize vibration and enhance the longevity of your equipment, ultimately improving overall productivity. With a commitment to excellence, we recognize the diverse requirements across industries. Each coupling is precision-manufactured to seamlessly integrate with your current systems. Our focus on reliability and durability ensures that every product undergoes rigorous testing to meet the highest standards.

How To Pick The Right Misaligned Shaft Coupling Supplies the World’s Top Brands Outperforms the Competition

When selecting the right misaligned shaft coupling, it’s crucial to consider both the specific application and the manufacturer’s expertise. Misalignment can occur due to various factors, including installation errors, thermal expansion, or wear over time. The ideal coupling should be capable of accommodating these misalignments while providing reliable performance and durability. Experience plays a vital role; a company with a rich history in valve fitting production is likely to possess the necessary insights into optimal coupling characteristics that can withstand diverse operational demands.

Global brands prioritize dependability and efficiency in their equipment, which is why sourcing from a supplier with a robust technical background is essential. The ideal supplier should not only have strong theoretical knowledge but also practical insights derived from years of hands-on experience in machinery equipment production. This makes all the difference in ensuring that the couplings can enhance performance, reduce downtime, and ultimately outperform competitors. By focusing on those suppliers that blend theoretical understanding with real-world application, companies can ensure that they select components that will support their operational goals effectively.

In a competitive landscape, it’s also vital to analyze the variety of coupling designs available. Each design caters to different types of misalignment and torque transmission capabilities. Buyers should consider those suppliers that offer a comprehensive range of couplings tailored to specific needs, ensuring compatibility with their existing machinery and efficiency in performance. The right coupling not only enhances the longevity of equipment but also boosts overall productivity, making it a key investment for companies globally seeking to maintain a competitive edge.

How To Pick The Right Misaligned Shaft Coupling Supplies the World’s Top Brands Outperforms the Competition

| Coupling Type | Maximum Misalignment (inches) | Torque Capacity (Nm) | Materials | Key Features |

|---|---|---|---|---|

| Elastomeric | 0.25 | 150 | Rubber, Steel | Vibration dampening, Lightweight |

| Gear Coupling | 0.75 | 300 | Steel, Alloy | High torque transmission, Durable |

| Fluid Coupling | 1.0 | 250 | Aluminum, Hydraulic Fluid | Slip protection, Smooth operation |

| Universal Joint | 1.5 | 200 | Steel, Composite | High flexibility, Compact design |

| Oldham Coupling | 0.5 | 100 | Aluminum, Plastic | Low backlash, Cost-effective |

How To Decide Between Misaligned Shaft Coupling Supplier Delivers Unmatched Quality

J

James Anderson

This product truly stands out in terms of quality. The after-sales support is also exceptional, ensuring a smooth experience.

25

June

2025

M

Mia Allen

Simply top-notch! The product quality is matched only by the exceptional customer care.

18

May

2025

A

Amelia Baker

The product is of high quality, and the after-sales team is incredibly professional and efficient.

21

May

2025

E

Evelyn Brown

Top-notch quality! The support team was thorough and very helpful.

23

June

2025

L

Lucy Price

What a wonderful find! The quality is excellent and so is the supportive customer service.

24

June

2025

C

Clara Evans

Absolute joy to use this product! Thankful for the attentive after-sales service.

01

June

2025