Marine Flexible Couplings: Quality OEM Solutions from Leading Manufacturers

Our marine flexible couplings are engineered to meet the rigorous demands of the maritime industry, ensuring exceptional performance and enduring durability. With a commitment to quality and precision, these couplings are essential for a variety of marine applications. Partnering with Sichuan Yining Machinery Equipment Co., Ltd. provides you access to advanced technology and innovative designs tailored specifically for marine engineering. We prioritize your operational success by delivering superior products that enhance efficiency and reliability. Let's discuss how our flexible couplings can support your business growth and meet your maritime needs effectively.Must-Know Tips For Marine Flexible Coupling Delivers Unmatched Quality Supplies the World’s Top Brands

When it comes to marine applications, the importance of utilizing high-quality flexible couplings cannot be overstated. These components play a crucial role in ensuring the efficient transmission of power while accommodating misalignment and vibration in equipment. For global buyers looking to invest in reliable marine flexible couplings, understanding key characteristics and best practices is essential.

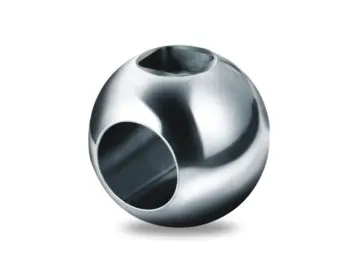

Firstly, consider the material composition of the couplings. High-grade materials not only enhance durability but also provide resistance to harsh marine environments. Look for couplings made from corrosion-resistant alloys or specialized polymers, ensuring optimal performance over time. Additionally, pay attention to the coupling design, which should facilitate easy installation and maintenance. Clever engineering, such as quick-release mechanisms, can greatly reduce downtime during vessel repairs.

Moreover, examine the supplier's experience and technical expertise. A company with a robust background in producing valve fittings and a team well-versed in the intricacies of marine equipment can offer invaluable insights into selecting the right coupling for specific applications. Their practical experience often translates into products that meet stringent industry standards, catering to the needs of top brands around the globe. By prioritizing these factors, global procurement professionals can secure marine flexible couplings that deliver unmatched quality and performance.

Must-Know Tips For Marine Flexible Coupling Delivers Unmatched Quality Supplies the World’s Top Brands

| Tip | Description | Application | Material | Load Capacity |

|---|---|---|---|---|

| Proper Alignment | Ensure all components are correctly aligned to prevent excessive wear. | Used in marine propulsion systems. | Aluminum Alloy | Up to 1000 Nm |

| Regular Maintenance | Periodic inspection to check for signs of fatigue or corrosion. | Applicable in ship engines and generators. | Stainless Steel | Up to 1500 Nm |

| Vibration Damping | Use flexible couplings to absorb vibration, reducing stress on components. | Inboard and outboard engine setups. | Polyurethane | Up to 1200 Nm |

| Heat Resistance | Select couplings that can withstand high temperatures to avoid failures. | High-performance marine engines. | Nylon Composite | Up to 900 Nm |

| Seal Integrity | Ensure seals are intact to maintain lubrication and prevent leaks. | Critical for all marine applications. | EPDM Rubber | Variable |

How Chinese Manufacturers Marine Flexible Coupling Market Leader Application

M

Mia Allen

Simply top-notch! The product quality is matched only by the exceptional customer care.

18

May

2025

L

Lucas Mitchell

Outstanding quality! Their after-sales service has been very responsive and helpful.

25

June

2025

L

Lucy Price

What a wonderful find! The quality is excellent and so is the supportive customer service.

24

June

2025

D

Daniel Harris

I am truly impressed! The level of care taken by the customer service team was exceptional.

10

May

2025

D

Dominic Parker

What a wonderful experience! The product quality is commendable and matched by outstanding support.

21

June

2025

L

Lewis Collins

Impressive quality and fantastic after-sales service! Highly recommend.

14

June

2025