Quality Industrial Valve Solutions from Top OEMs, Factories & Suppliers

When sourcing high-quality industrial valves, partnering with a trusted OEM supplier is essential. Sichuan Yining Machinery Equipment Co., Ltd. stands out as a reliable manufacturer committed to excellence. Their extensive range of industrial valves is engineered for durability and superior performance, catering to diverse applications. I value their meticulous approach to manufacturing and stringent quality assurance processes. The knowledgeable team is always available to address inquiries and accommodate customization requests, ensuring a smooth procurement experience. From ball valves to gate valves and check valves, their options are dependable and of the highest quality. For those in need of trustworthy industrial valves, Sichuan Yining Machinery Equipment Co., Ltd. is an excellent choice.Key Steps to Choosing Industrial Valve Winning in 2025 From Concept to Delivery

Choosing the right industrial valve is a crucial decision that can impact the efficiency and reliability of your operations in 2025 and beyond. As industries increasingly focus on sustainability and innovation, understanding the key steps to select the optimal valve can make all the difference. Begin by assessing your specific operational requirements. Consider factors like the media being handled, temperature and pressure conditions, and the desired flow control characteristics. This initial evaluation ensures that the valve selected aligns well with project specifications.

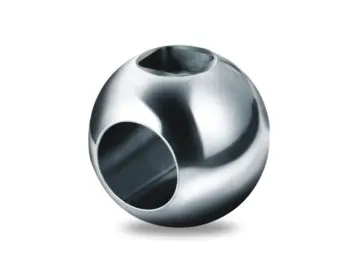

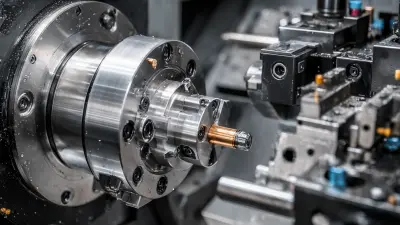

Next, engage in a thorough analysis of the different valve types available on the market. From gate valves to ball valves and butterfly valves, each type has its unique strengths and weaknesses. It's vital to collaborate with a knowledgeable technical team that can provide expertise on material selection and design considerations. Look for manufacturers that prioritize quality and have a proven track record in producing reliable products.

Finally, ensure that you thoroughly evaluate the logistics associated with the procurement process. The journey from concept to delivery involves careful planning, including lead times, shipping options, and compliance with international standards. Establishing a solid relationship with your chosen supplier can streamline this process and mitigate potential risks. By following these key steps, you will be well-equipped to make informed decisions that drive success and innovation in your operations.

Key Steps to Choosing Industrial Valve Winning in 2025 From Concept to Delivery

| Step | Description | Key Considerations | Expected Outcome |

|---|---|---|---|

| 1. Define Requirements | Identify the application needs, fluid types, pressure, and temperature considerations. | Material compatibility, environmental conditions, regulatory compliance. | Clear understanding of valve specifications and performance expectations. |

| 2. Research Valve Types | Explore different types of valves such as gate, globe, ball, and butterfly valves. | Flow characteristics, maintenance needs, and installation space. | Selection of the most suitable valve type for specific application. |

| 3. Evaluate Suppliers | Assess supplier credibility, certifications, and past performance. | Quality assurance, delivery times, after-sales support. | Establish strong partnerships with reliable suppliers. |

| 4. Request Prototypes | Obtain sample valves for testing in real conditions. | Prototype performance validation, user feedback. | Confirm valve suitability and reliability prior to full order. |

| 5. Finalize Specifications | Finalize technical specifications and order requirements. | Cost analysis, delivery schedule, warranty terms. | Accurate and complete order ensuring satisfaction. |

| 6. Order Placement | Place the final order with selected supplier. | Payment terms, delivery confirmation, production timeline. | Commencement of the delivery process. |

| 7. Delivery and Installation | Receive and install the valves according to specifications. | Installation guidelines, safety procedures, and testing protocols. | Operational readiness of the valve system. |

Best Chinese Industrial Valve Custom Solutions, Industry Giant

M

Michael Thompson

The quality of the product exceeded my expectations. The team has been incredibly supportive throughout the entire purchasing process.

02

June

2025

A

Aiden Scott

The quality is impressive! Customer support was friendly and extremely knowledgeable.

09

June

2025

C

Chloe Walker

Stellar product! I applaud the professionalism exhibited by the customer service team.

03

July

2025

A

Abigail Nelson

Remarkable experience! The quality is great, and so is the after-sales service.

12

June

2025

L

Lucy Price

What a wonderful find! The quality is excellent and so is the supportive customer service.

24

June

2025

A

Angela Clark

Amazing product! The after-sales service team was incredibly helpful and engaged.

19

June

2025