Hardened Valve Seats for Unleaded Fuel - OEM Manufacturers & Quality Supply

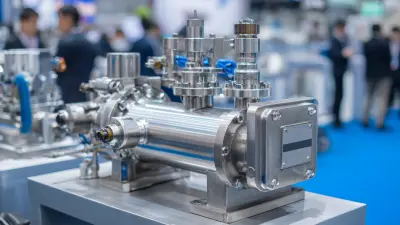

Enhance your engine performance with our top-quality unleaded hardened valve seats. As a leading manufacturer and supplier, we prioritize exceptional quality and adherence to OEM standards, ensuring your specifications are met for longevity and reliability. Whether you operate a machinery supply business or require components for your manufacturing processes, we offer dependable solutions tailored to your needs. With years of expertise, Sichuan Yining Machinery Equipment Co., Ltd. is committed to providing outstanding service and competitive pricing to boost your machinery’s performance.

Effective Ways To Hardened Valve Seats Unleaded Manufacturer Products

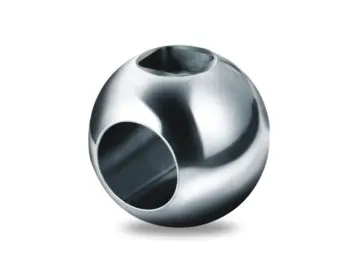

In today's competitive manufacturing landscape, ensuring the durability and reliability of valve seats is paramount, especially for unleaded products that require strict adherence to safety and environmental regulations. One effective method to enhance the hardness of valve seats is through advanced heat treatment processes. This technique increases the wear resistance and lifespan of the valves, making them suitable for a variety of demanding applications across industries.

Additionally, the incorporation of modern materials, such as advanced alloys and composites, can significantly improve the performance of valve seats. When selecting a manufacturer, it is crucial to look for those who utilize high-quality raw materials and employ rigorous quality control measures. This not only guarantees the longevity of the products but also contributes to better cost-performance over time.

Lastly, continuous innovation in manufacturing techniques, such as precision machining and surface finishing, can further optimize the hardness of valve seats. By partnering with manufacturers that invest in research and development, global buyers can ensure they receive cutting-edge products that meet their operational needs, while also conforming to the latest industry standards. Exploring these avenues will ultimately lead to superior valve fittings that stand the test of time.

Effective Ways To Hardened Valve Seats Unleaded Manufacturer Products

| Method | Material Used | Benefits | Applications |

|---|---|---|---|

| Carburizing | Carbon-rich gas | Improves hardness and wear resistance | Internal combustion engines |

| Nitriding | Nitrogen-rich environment | Enhances surface hardness | Gear and valve applications |

| Chromium Plating | Electroplated chromium | Corrosion resistance and durability | Automotive and industrial valves |

| Ceramic Coating | Ceramic materials | High temperature resistance | High-performance engines |

Making Smart Choices Hardened Valve Seats Unleaded Manufacturer Is The Best

L

Liam Adams

Fantastic quality! Their after-sales support team is truly knowledgeable and dedicated.

15

June

2025

J

James Collins

Top quality product! The after-sales support was proactive and highly skilled.

18

May

2025

S

Sophie Lee

Absolutely an amazing product! The after-sales team was knowledgeable and responsive.

21

June

2025

G

Grace Hernandez

Great product choice! The level of respect and professionalism shown by the support staff was fantastic.

09

May

2025

C

Chase Anderson

Outstanding value! The follow-up from the after-sales team was very professional.

04

June

2025

C

Cameron Morgan

Superb quality! The after-sales support team was remarkably resourceful.

20

June

2025