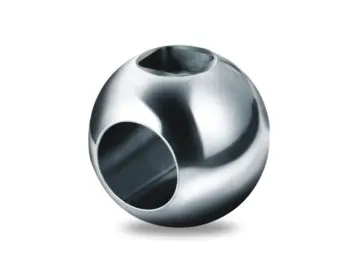

High-Quality Forgings for Reliable Valve Components Solutions

At Sichuan Yining Machinery Equipment Co., Ltd., we specialize in high-quality forgings for valve components, prioritizing reliability and durability for various industries. Our precision-engineered forgings offer exceptional strength and wear resistance, ensuring the optimal performance and longevity of valve systems. Committed to quality and customer satisfaction, we tailor our products to meet your specific requirements and adhere to strict industry standards. Whether you require standard sizes or custom solutions, we are dedicated to supporting your needs and helping you achieve your project objectives efficiently.

How To Find The Best Forgings For Valve Components in 2025 Products

When seeking the best forgings for valve components in 2025, buyers should prioritize several key factors to ensure quality and reliability. First, it is essential to collaborate with manufacturers that possess a strong technical background in forging processes. A knowledgeable team well-versed in both theoretical underpinnings and hands-on experience can significantly influence the production of high-quality valve components. These experts understand the intricacies of material selection, heat treatment, and machining, which are critical to achieving optimal performance and durability.

Secondly, evaluating the manufacturer’s production experience and management practices is vital. Companies with a long-standing history in the industry tend to have refined their processes and adopted best practices over time. This not only enhances the consistency of their products but also leads to more innovative solutions to meet specific needs. Buyers should look for partners who are committed to continuous improvement and have a proven track record of meeting international standards.

Finally, leveraging technology in the selection process can greatly benefit global buyers. Advanced tools for material analysis, design simulations, and quality control ensure that the forgings meet stringent performance criteria. By combining expert knowledge with state-of-the-art technology, buyers can secure the best forgings for their valve components, driving efficiency and reliability in their operations for years to come.

How To Find The Best Forgings For Valve Components in 2025 Products

| Material | Forging Process | Applications | Typical Hardness (HRc) | Weight Range (kg) |

|---|---|---|---|---|

| Stainless Steel 316 | Closed Die Forging | Pipes and Fittings | 28-32 | 0.5 - 5 |

| Carbon Steel A105 | Open Die Forging | Valves and Flanges | 25-30 | 1 - 10 |

| Alloy Steel 4140 | Hot Forging | Heavy Machinery | 30-40 | 2 - 25 |

| Nickel Alloy Inconel 625 | Precision Forging | Aerospace Applications | 35-45 | 0.1 - 3 |

| Titanium Alloy Ti-6Al-4V | Beta Forging | Medical Implants | 36-40 | 0.3 - 5 |

Not to Be Missed Forgings For Valve Components Exceeds Industry Benchmarks Industry Leaders

C

Chloe Scott

Highly recommend! This product truly delivers, and the customer service was remarkable.

23

June

2025

H

Henry Martinez

I love this product! The after-sales staff provided a level of service that was truly professional.

03

July

2025

N

Noah Rogers

Exceptional quality! Their dedication to customer satisfaction is evident in their service.

26

June

2025

D

Daniel Harris

I am truly impressed! The level of care taken by the customer service team was exceptional.

10

May

2025

C

Clara Evans

Absolute joy to use this product! Thankful for the attentive after-sales service.

01

June

2025

O

Oliver Clark

I’m beyond satisfied! The level of professionalism from the after-sales team is second to none.

04

July

2025