Electric Motor Coupling: Leading OEM Suppliers & Manufacturers You Can Trust

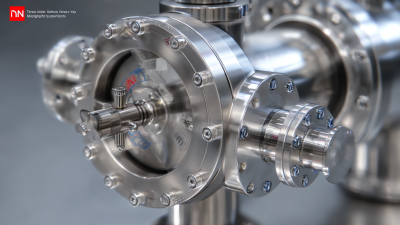

Enhance your factory operations with our dependable electric motor couplings, specifically designed for a variety of industrial applications. At Sichuan Yining Machinery Equipment Co., Ltd., we cater to the unique needs of each facility, offering a diverse selection of couplings that integrate seamlessly with your existing equipment. Our electric motor couplings are crafted for exceptional durability and performance, ensuring effective power transfer while minimizing wear and tear. Whether you're sourcing high-quality components or aiming to boost operational efficiency, our products deliver the reliability you need.

In-Depth Analysis of Methods Electric Motor Coupling Is The Best Stands Out

In the realm of industrial machinery, the coupling of electric motors is pivotal to efficiency and performance. At Sichuan Yining Machinery Equipment Co., Ltd., our extensive experience in processing and producing various valve fittings since 2005 has endowed us with insights into the optimal methods for electric motor coupling. Our technical team, equipped with rich theoretical knowledge and practical expertise, strives to provide solutions that not only meet but exceed industry standards.

One standout method for electric motor coupling is the use of flexible couplings, which effectively accommodate misalignments and reduce vibrations, ensuring smoother operation and longevity of machinery. Moreover, the integration of high-quality materials in our couplings enhances robustness and reliability, addressing the diverse needs of global buyers. With our deep understanding of mechanical dynamics, we are equipped to guide our clients in selecting the best coupling methods that align with their specific requirements.

As we move towards an increasingly interconnected global market, it is imperative to adopt innovative approaches to motor coupling. Sichuan Yining Machinery Equipment Co., Ltd. is committed to delivering cutting-edge solutions tailored to the unique challenges faced by our clientele. By choosing our products, global purchasers can ensure optimal performance and cost-effectiveness, positioning themselves for success in an ever-evolving landscape.

In-Depth Analysis of Methods Electric Motor Coupling Is The Best Stands Out

| Method | Advantages | Disadvantages | Efficiency (%) | Cost ($) |

|---|---|---|---|---|

| Rigid Coupling | High strength, simple installation | No misalignment compensation | 95 | 50 |

| Flexible Coupling | Compensates misalignment, shock absorption | Lower torque capacity | 90 | 75 |

| Oldham Coupling | Good for angular misalignment | Lower torque transmission | 85 | 60 |

| Synchronous Coupling | High efficiency, minimal loss | Complex installation | 98 | 120 |

| Universal Joint | Accepts high angles of misalignment | Potential for vibration | 80 | 70 |

Effective Ways To Electric Motor Coupling Global Reach Industry Leaders

J

James Anderson

This product truly stands out in terms of quality. The after-sales support is also exceptional, ensuring a smooth experience.

25

June

2025

A

Avery Reed

This product is a game changer! The commitment shown by their support team is commendable.

17

June

2025

A

Alyssa Hill

I love this product! The ongoing support reflected a dedication to customer satisfaction.

19

June

2025

A

Alexander Davis

Excellent quality! They offered exceptional post-purchase assistance.

21

June

2025

C

Chase Anderson

Outstanding value! The follow-up from the after-sales team was very professional.

04

June

2025

A

Audrey Perez

Wonderful product! Their customer support team was incredibly responsive and helpful.

05

July

2025