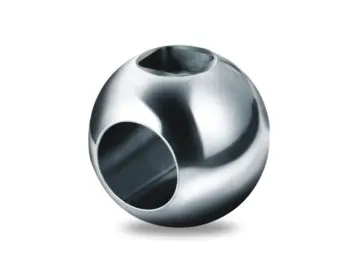

Double Seat Ball Valves: Boost Performance and Reliability for Your Applications

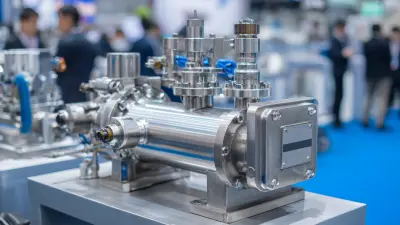

Our Double Seat Ball Valves are engineered for superior performance and reliability in fluid control across various high-pressure applications. These valves boast exceptional sealing properties and durability, making them suitable for industries such as oil and gas, chemical processing, and water treatment. Designed for seamless operation, they significantly reduce wear and tear while delivering leakage-free performance. With their precise control capabilities, our valves facilitate smooth on-off and throttling functions essential for efficient process management. At Sichuan Yining Machinery Equipment Co., Ltd., we are committed to meeting your specific needs by providing customized solutions. Each valve undergoes rigorous testing, and our dedicated support team is readily available to assist you. Count on us for quality, dependability, and competitive pricing for every order, regardless of size. Transform your operations with our outstanding Double Seat Ball Valves.

Best Options For Double Seat Ball Valves Products Manufacturer

When it comes to sourcing double seat ball valves, finding a reliable manufacturer is crucial for ensuring quality and performance. Double seat ball valves are essential components used in various industries, including oil and gas, water treatment, and chemical processing, due to their efficiency in controlling fluid flow and minimizing leakage. As a global purchaser, your success hinges on partnering with a manufacturer that not only understands the technical intricacies of valve engineering but also possesses the capability to deliver consistent and high-quality products.

The ideal manufacturer should have a strong technical team, combining theoretical knowledge with hands-on experience to optimize production processes and innovate on conventional designs. This expertise translates into valves that meet rigorous international standards, providing you with assurance in product reliability. Moreover, an established manufacturer should have demonstrated management and production experience, ensuring that they can adapt to fluctuating market demands while maintaining the integrity of their offerings.

Ultimately, selecting the right double seat ball valve manufacturer involves partnering with a team that prioritizes quality, efficiency, and customer service. As you explore your options, look for manufacturers that align with your specific needs and offer a proven track record in valve production, enabling you to secure the best products for your operations.

Best Options For Double Seat Ball Valves Products Manufacturer

| Product Type | Material | Size Range (inch) | Pressure Rating (PSI) | Temperature Range (°F) | Certifications |

|---|---|---|---|---|---|

| Double Seat Ball Valve | Stainless Steel | 1/2 - 4 | 150 - 600 | -20 to 400 | ISO 9001, API 6D |

| Double Seat Ball Valve | Carbon Steel | 1 - 6 | 150 - 300 | -20 to 300 | CE, ASTM |

| Double Seat Ball Valve | PVC | 1/2 - 2 | 80 - 150 | 32 to 140 | NSF, RoHS |

Smart Ways To Double Seat Ball Valves Outperforms the Competition Winning in 2025

A

Ava Hall

Excellent product! I was especially impressed by the thoroughness and friendliness of the after-sales service.

08

May

2025

N

Nora Carter

Thrilled with the quality of this item! Customer care was attentive and informative.

24

May

2025

A

Aiden Scott

The quality is impressive! Customer support was friendly and extremely knowledgeable.

09

June

2025

N

Nathan Martinez

Absolutely thrilled with this purchase! Their team provided excellent ongoing support.

17

June

2025

L

Landon Turner

Impressive craftsmanship! The response time from the support team was remarkably fast.

02

July

2025

N

Nicholas Roberts

High quality and excellent follow-up service! A pleasure to work with them.

22

June

2025