Best Chemical Resistant Ball Valves for Enhanced Durability and Performance

Our Chemical Resistant Ball Valves deliver exceptional performance in demanding environments. Engineered to handle various corrosive substances, these valves prioritize safety and efficiency for your operations. With a focus on durability and reliability, they meet the exacting standards of your industry. Additionally, their user-friendly design ensures straightforward installation and low maintenance, providing a cost-effective solution for your piping requirements. Trust these robust valves to enhance your operational efficiency.10 tips Chemical Resistant Ball Valves Where Innovation Meets 2025 Your End-to-End Solution

In today’s rapidly evolving industrial landscape, chemical-resistant ball valves are vital for operations that handle aggressive substances. As we look toward 2025, innovation plays a crucial role in enhancing the reliability and efficiency of these components. Here are ten essential tips to consider when choosing chemical-resistant ball valves that can meet both current and future demands.

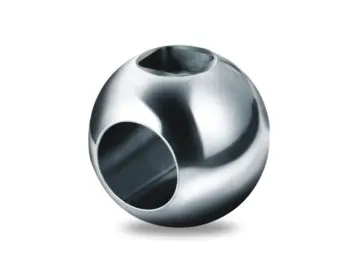

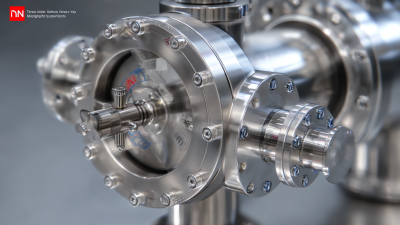

First, focus on the materials used in manufacturing. High-performance materials such as PTFE, PEEK, and other specialized polymers can withstand high pressures and corrosive environments. Ensure that the valves are designed for specific chemicals, as compatibility can significantly affect their lifespan and performance. Additionally, consider the valve's design, including its sealing technology. Advanced seals can prevent leaks and ensure a longer operational life, reducing downtime and maintenance costs.

Second, prioritize suppliers that emphasize technological advancements in their products. Features such as automation readiness, smart sensors for real-time monitoring, and enhanced ease of maintenance can provide significant advantages. Partnering with companies that demonstrate a commitment to innovation ensures you stay ahead in efficiency and reliability, maximizing your overall investment. In a competitive marketplace, these considerations not only improve your operational capabilities but also enhance safety standards, crucial for any facility dealing with hazardous materials.

10 Tips for Chemical Resistant Ball Valves: Where Innovation Meets 2025 - Your End-to-End Solution

| Tip Number | Tip Description | Material Recommendation | Application Suitability |

|---|---|---|---|

| 1 | Select the right valve type based on chemical exposure. | PTFE (Teflon) | Corrosive chemicals |

| 2 | Ensure proper installation to avoid leaks. | PVDF | Aqueous solutions |

| 3 | Regular maintenance checks for optimal performance. | SS 316 | General applications |

| 4 | Use valves with electro-polished surfaces where applicable. | Hastelloy | High-purity applications |

| 5 | Follow manufacturer guidelines for chemical compatibility. | PVC | Acids and bases |

| 6 | Consider actuated valves for controlled operation. | FRP | Bulk liquid transport |

| 7 | Innovate with smart valve technology for process automation. | Ceramic | Aggressive environments |

| 8 | Train personnel on best practices for handling and installation. | Bronze | Pharmaceuticals |

| 9 | Optimize valve size and flow rate for efficiency. | Alloy 20 | Chemical processing |

| 10 | Consider end-of-life recycling options for sustainable practices. | Nylon | Water and sewage |

Why Trust Chemical Resistant Ball Valves Sets the Industry Standard Global Reach

E

Ella Mitchell

What a delight! The quality stands out, and the customer support was exceptional.

21

May

2025

E

Elijah Murphy

High quality and great performance! The support staff was engaging and very helpful.

05

June

2025

R

Ryan Lewis

Quality product that performs beautifully! Customer service was outstanding.

02

June

2025

V

Victor Young

The product far surpassed my expectations! Their support team was top-notch.

19

June

2025

D

Daisy Taylor

Incredibly high quality! The customer service team stood out for their care and expertise.

05

June

2025

A

Audrey Perez

Wonderful product! Their customer support team was incredibly responsive and helpful.

05

July

2025