The valve bonnet plays a crucial role in the functionality of valves across industries. It houses various components, ensuring proper sealing and pressure maintenance. Different types of valve bonnets cater to specific applications, such as gate, globe, and ball valves. Each type offers unique advantages, impacting overall performance.

In industries like oil and gas, the choice of valve bonnet can be pivotal. An incorrect selection may lead to leaks or operational failures. Additionally, materials used in valve bonnets must withstand harsh conditions. The right material can enhance durability and reliability. However, finding the balance between cost and quality often proves challenging.

As technology advances, new designs emerge. Innovations in valve bonnets aim to improve efficiency and reduce maintenance needs. Yet, some designs may not always address all reliability concerns. Ongoing research and development remain essential. Industries must stay alert to evolving trends, ensuring their operations optimize performance with the right valve bonnet choices.

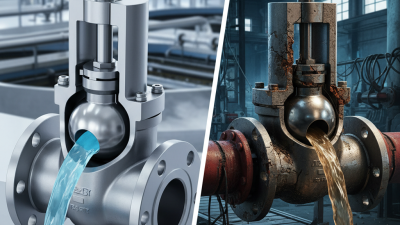

Valve bonnets play a critical role in the overall functionality of valves in various industries. They protect the valve internal mechanisms and ensure proper sealing. There are several types of valve bonnets, each serving unique applications in sectors such as oil and gas, water treatment, and manufacturing. For instance, bolted bonnets offer ease of maintenance but can be prone to leakage under high pressure. A 2022 industry report indicated that about 40% of maintenance issues stem from bonnet failures.

Another common type is the welded bonnet. This design is favored for high-pressure applications, providing a strong seal. However, once installed, repairing a welded bonnet can be challenging. Industry data suggests that around 30% of long-term operational costs are tied to repairing or replacing welded designs. In contrast, union bonnets allow for quick disassembly, yet they might not withstand extreme conditions as effectively.

Specialized bonnets are engineered for specific needs, such as cryogenic or high-temperature applications. These often require advanced materials and designs to ensure safety and performance. While innovations are on the rise, not all designs are perfect; approximately 15% of users report ongoing leakage problems, prompting a reconsideration of design choices. Each type of bonnet must be evaluated based on its application to ensure reliability and safety.

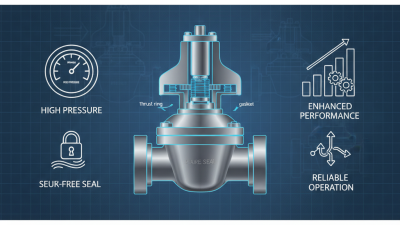

When discussing valve bonnet designs, various characteristics stand out. A common type is the bolted bonnet. This design is favored for its ease of maintenance. In typical operations, it allows quick access to internal components. However, bolted bonnets can also struggle with sealing over time.

Another notable design is the welded bonnet. This construction offers greater strength. It provides a leak-proof solution that many industries need. Yet, it complicates repairs and can lead to increased downtime. Welded bonnets require careful inspection to avoid hidden issues.

Furthermore, the integral bonnet combines body and bonnet into one piece. This simplicity enhances reliability and reduces leak risks. Still, it poses challenges during installation and limits flexibility. Each design has its strengths and weaknesses. The choice may depend on specific operational needs and conditions. Often, a balance must be struck between accessibility and durability.

Valve bonnets play a crucial role across various industries. In the oil and gas sector, for instance, they are vital for maintaining pressure and preventing leaks. According to a report by the International Energy Agency (IEA), nearly 90% of offshore oil and gas operations rely on robust valve designs. This highlights the importance of selecting the right bonnet type to ensure operational safety.

In the water treatment industry, bonnet design is equally essential. Many facilities use bonneted valves to manage flow and hydraulic pressure. A study from Water Research Foundation indicates that leaks can cause a loss of up to 30% of treated water. Effective bonnets can help mitigate these issues. However, improper maintenance can lead to malfunction. Operators often overlook regular inspections, compromising system efficiency.

Chemical manufacturing also employs specialized valve bonnets. These structures must withstand corrosive environments. According to research by the Chemical Engineering Journal, the failure rate of certain bonnet types can exceed 15% in high-stress conditions. This underscores the need for careful evaluations during selection. Operators sometimes underestimate the impact of environmental factors, increasing risks in plant operations.

| Valve Bonnet Type | Description | Common Applications | Industry |

|---|---|---|---|

| Bolted Bonnet | Features a bonnet that is bolted to the valve body, allowing for easy access and maintenance. | High-pressure applications requiring maintenance | Oil and Gas |

| Welded Bonnet | A bonnet that is permanently welded to the valve body, providing a tighter seal. | Severe service applications where leakage is critical | Chemical Processing |

| Screwed Bonnet | Utilizes screw threads to attach the bonnet to the valve body. | Low-pressure applications and easy disassembly | Water Treatment |

| Union Bonnet | Features a union connection for easy removal of the bonnet. | Applications requiring frequent maintenance and adjustments | HVAC Systems |

| Integral Bonnet | A design where the bonnet is an integrated part of the valve body. | Applications with space constraints | Pharmaceutical |

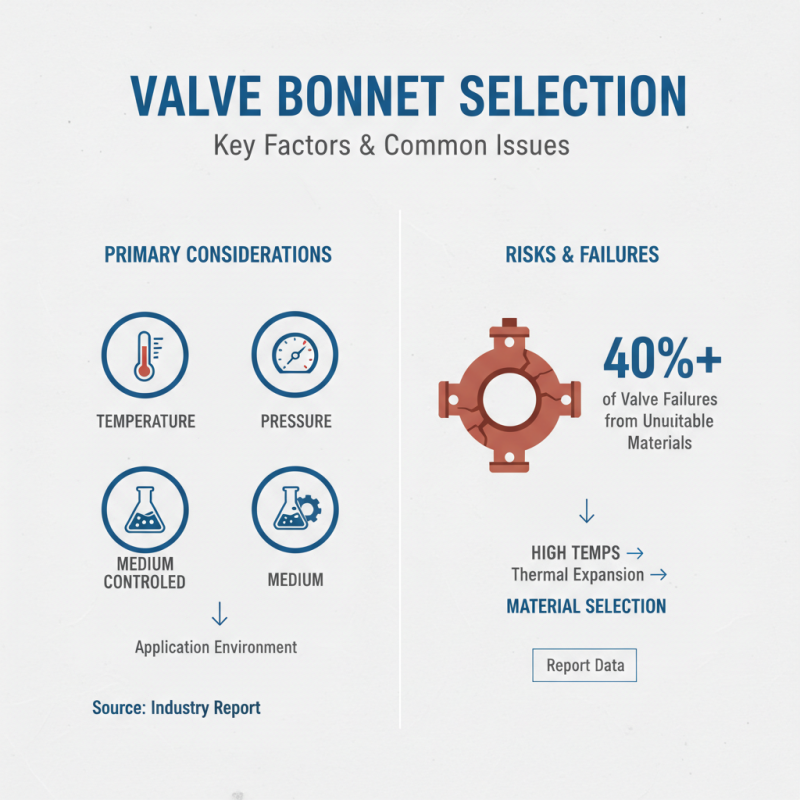

When selecting valve bonnet types, several factors come into play. The primary consideration is the application environment. Temperature, pressure, and the medium being controlled all dictate the appropriate bonnet design. For example, high temperatures may require materials that can withstand thermal expansion. A recent report indicated that over 40% of valve failures in industrial settings result from unsuitable materials.

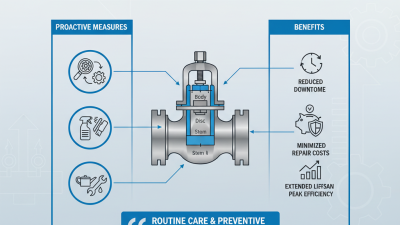

Another key factor is maintenance requirements. Certain bonnet designs allow easier access for repair and inspection. In industries like oil and gas, where downtime is costly, this factor is critical. Studies suggest that every hour of unexpected downtime can cost an operation between $10,000 to $100,000. Therefore, serviceability cannot be overlooked.

Cost implications also influence choice. While some bonnets are more expensive upfront, they may offer long-term savings. A study highlighted that investing in higher-quality materials could reduce the frequency of maintenance by 30%. This reflects a need to weigh initial expenses against potential future savings. Moreover, choosing a bonnet type must align with operational standards and safety regulations. Ignoring these can lead to compliance issues that are hard to rectify later.

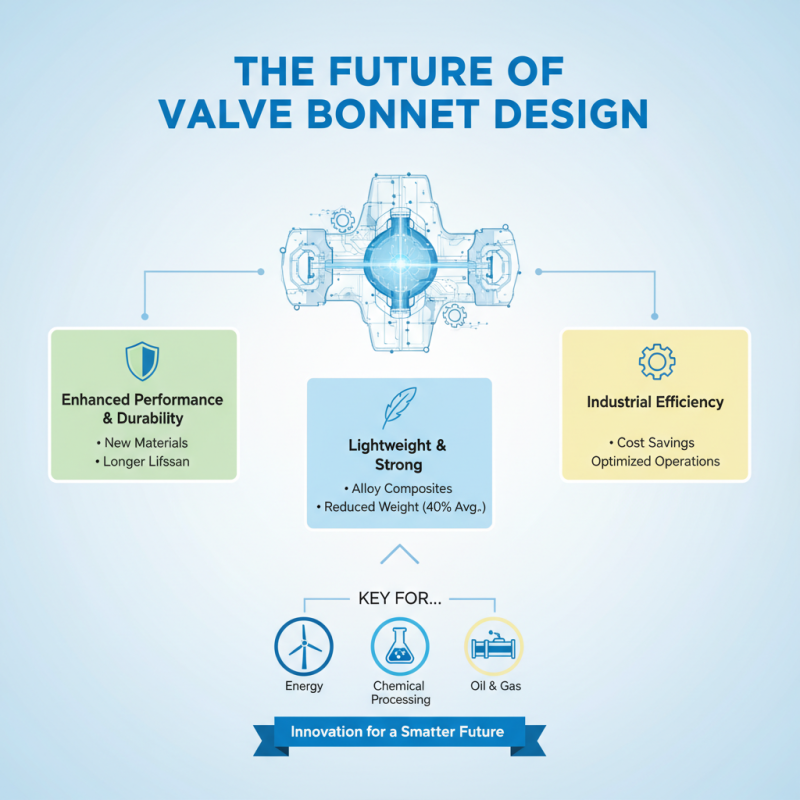

The future of valve bonnet design is evolving rapidly. New materials enhance performance and durability. Lightweight alloys reduce weight while maintaining strength. This shift is key for industries focusing on efficiency.

Technology integration is another trend. Smart monitoring systems allow real-time data collection from valve bonnets. This can improve reliability and maintenance schedules. Yet, not all systems deliver accurate readings. Reliability is still a concern in some designs.

Tips: Always assess the compatibility of materials with your specific application. New doesn't always mean better; consider proven designs too. A balance of innovation and tradition often yields the best results.