In modern industrial systems, efficiency often hinges on the right technologies. One key area to focus on is the selection of effective Valve Automation Components. These components play a vital role in enhancing performance and optimizing processes. Selecting the appropriate valve automation can drastically improve fluid control.

Many organizations overlook the significance of these components. This mistake can lead to inefficiencies and increased operation costs. Advances in valve technology have introduced various automation solutions. However, not all options are created equal. It's essential to reflect on the specific needs of a system when choosing components.

Understanding the top valve automation components is crucial. These features can make or break an operation's efficiency. Components such as actuators, sensors, and controllers provide clear advantages. Investing in the right components is an ongoing journey. Take time to evaluate options carefully. The right choices encourage better production and can save significant resources in the long run.

Valve automation components are critical for enhancing operational efficiency. These components streamline processes, reducing the need for manual control. Reports indicate that automated valves can improve response times by 25%. This is significant in industries where precision matters, such as oil and gas.

When considering these components, focus on their integration capability. Not all components work seamlessly together. A poor selection can lead to frequent breakdowns. Experts advise that around 10% of automation failures are due to component mismatch.

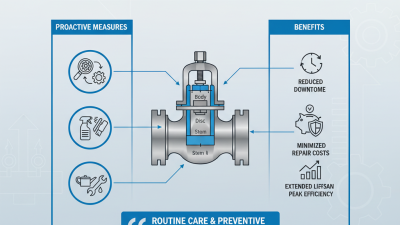

Tips: Regular maintenance can extend the life of your automation system. Additionally, investing in training for your team is vital. Knowledgeable personnel can swiftly identify issues.

Efficiency is often hindered by oversight. Many organizations overlook the importance of updating their automation technology. Not adapting may result in lagging performance. Ultimately, understanding and investing in valve automation components is essential for any forward-looking operation.

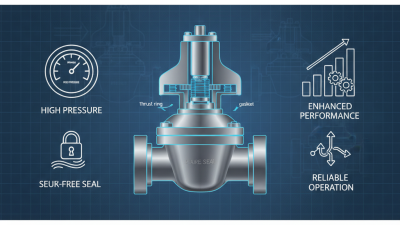

When it comes to valve automation, efficient actuators play a crucial role. They must provide reliable and precise control. The best actuators respond quickly to signals. This ensures the flow of materials is optimal and well-regulated. Key features include speed, torque, and compatibility with various systems.

Tip: Look for actuators that offer feedback capabilities. This can help in monitoring performance and adjusting settings in real-time. Proper sizing matters too. Over-sized actuators can lead to waste. Under-sized options may fail to perform.

Another important aspect is energy efficiency. Selecting actuators that consume less power can reduce operational costs. Consider features like soft-start and adjustable speed. These can enhance overall efficiency. While automation technology advances, it's crucial not to overlook maintenance. Regular checks can identify issues early.

Tip: Create a maintenance schedule. This ensures actuators work at peak performance. Neglecting small issues can lead to bigger problems down the line. Remember, an efficient actuator can transform your entire valve automation process.

| Component | Key Feature | Efficiency Benefit | Application |

|---|---|---|---|

| Electric Actuator | Precise Control | Reduced energy consumption | Industrial Automation |

| Pneumatic Actuator | Fast Response Time | Improved throughput | Process Control |

| Hydraulic Actuator | High Torque Output | Enhanced performance | Heavy Machinery |

| Positioner | Feedback Control | Increased accuracy | Valve Management |

| Solenoid Valve | Electromechanical Control | Quick actuation | Fluid Control |

| Limit Switch | Position Indication | Operational safety | Automation Systems |

| Flow Meter | Real-time Measurement | Process optimization | Fluid Dynamics |

| Valves | Leak-proof Design | Reduced waste | Pipeline Operations |

| Control Systems | Automated Control | Optimized Efficiency | Smart Facilities |

| Actuator Accessories | Add-ons for Functionality | Enhanced versatility | Custom Applications |

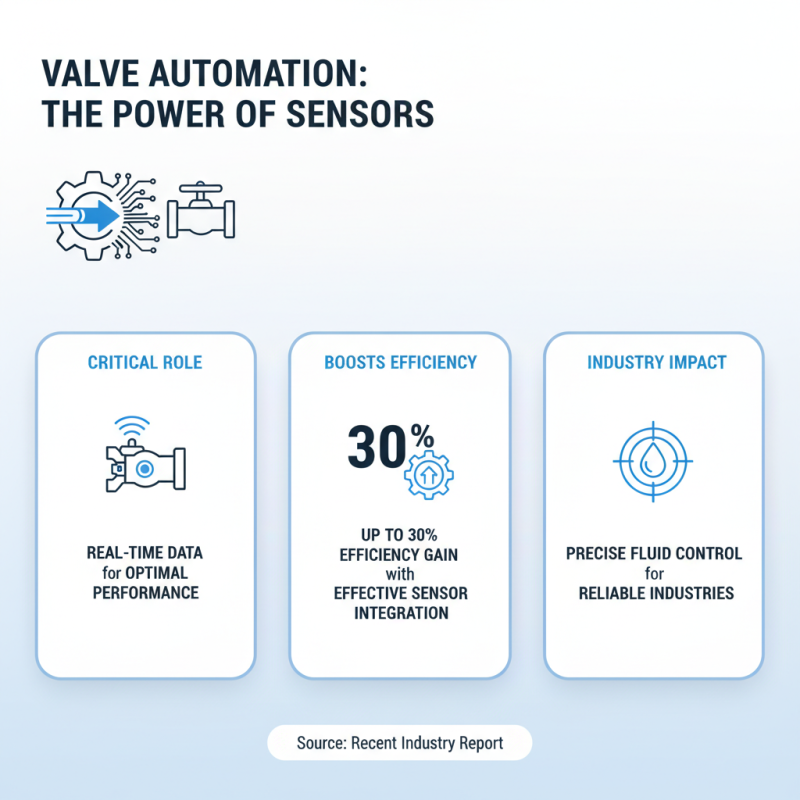

In valve automation, sensors play a critical role. They provide real-time data, ensuring optimal performance. According to a recent industry report, effective sensor integration can boost efficiency by up to 30%. This is significant for industries that rely on precise fluid control.

Pressure sensors are essential in valve automation. They monitor system pressure, preventing failures and minimizing downtime. Another crucial type is the temperature sensor. It helps maintain safe operating conditions, which can reduce accidents. Flow sensors also stand out. They ensure the right amount of fluid passes through valves at the correct times.

However, not all sensors are created equal. Some manufacturers integrate poor-quality sensors, leading to inaccuracies. A study found that around 25% of sensor failures stem from substandard components. This emphasizes the importance of proper selection. Investing in reliable sensors is not just important; it's necessary for efficient automation.

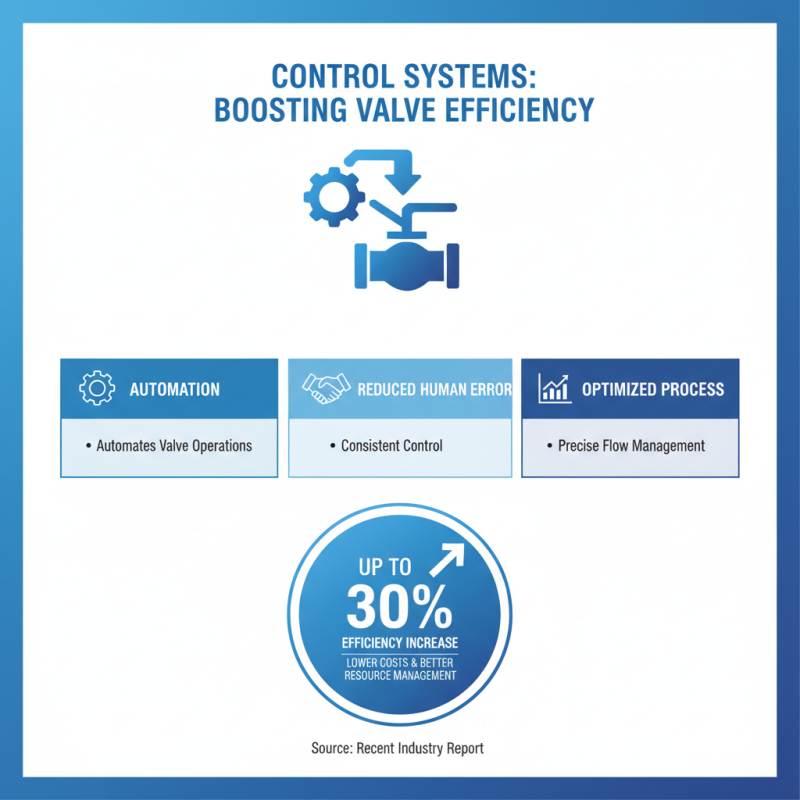

Control systems play a crucial role in enhancing valve efficiency. They automate valve operations, reducing human error and optimizing process control. According to a recent industry report, systems with advanced automation can increase efficiency by up to 30%. This significant improvement means lower operational costs and better resource management.

Monitoring systems are integral to this process. They provide real-time data on performance metrics. This helps to identify issues early, preventing costly downtimes. A study highlighted that 90% of companies that adopted smart control systems saw improved reliability in valve operations. Yet, not all systems deliver. Some might struggle with integration or require frequent adjustments.

Effective control systems must also adapt to varying conditions. Rigid systems can limit operational flexibility. In a rapidly changing environment, adaptability is essential. Data from recent surveys indicate that 50% of operators report challenges in this area. Continuous improvement and regular system assessments are necessary to ensure peak performance.

Integrated communication protocols play a pivotal role in enhancing automation efficiency. With the rise of Industry 4.0, data exchange has become seamless. A report by the International Society of Automation reveals that automation systems with integrated protocols can boost productivity by up to 30%. This is a remarkable figure that shows the direct correlation between communication and operational output.

Automation systems need to communicate effectively with various components. Poor connectivity often leads to delays and errors. According to a study by MarketsandMarkets, 25% of companies still rely on outdated communication technology. This reliance results in lost time and increased operational costs. Integrated protocols, like OPC UA, can address these issues. They allow for real-time data sharing across devices, enabling quicker decision-making.

However, not all companies adopt these new protocols. Resistance to change is common. Many organizations fear upfront investment costs or lack knowledge about implementation. Despite this, the potential benefits are evident. Research shows that organizations utilizing integrated protocols often see a return on investment within a year. The imperative is clear: embracing modern communication methods can significantly enhance operational efficiency.

This bar chart illustrates the importance and efficiency benefits of various valve automation components in industrial settings. The data reflects usage percentages and efficiency improvements through integrated communication protocols.