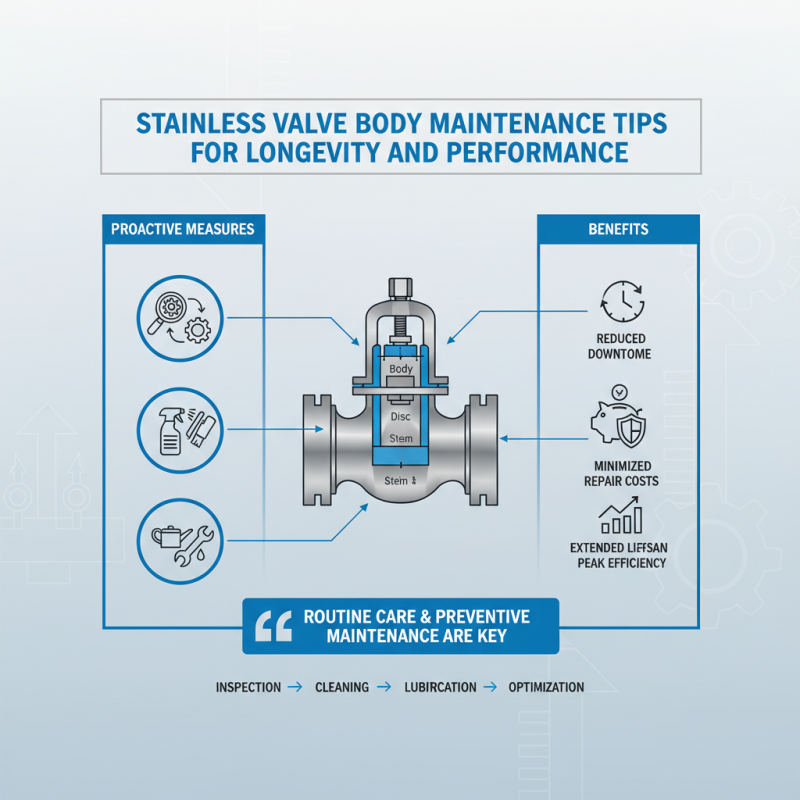

In the realm of industrial equipment, the maintenance of a Stainless Valve Body is paramount for ensuring longevity and optimal performance. John Smith, a recognized expert in valve engineering, once stated, “The key to prolonging the life of a Stainless Valve Body lies not only in quality manufacturing but also in routine care and preventive maintenance.” This insight emphasizes that proactive measures can significantly enhance the efficiency and durability of stainless steel valves used in various applications.

Regular maintenance of a Stainless Valve Body involves thorough inspections, cleaning, and ensuring proper lubrication. Neglecting these essential practices can lead to corrosion, leaks, and ultimately, premature failure of the valve. In addition, understanding the specific operating conditions and environmental factors that affect the valve's performance can help in creating an effective maintenance schedule tailored to the valve’s operational demands.

By prioritizing the upkeep of Stainless Valve Bodies, industries can reduce downtime, minimize repair costs, and extend the lifespan of their valves. Implementing these maintenance tips not only protects the investment but also ensures that the system operates at peak efficiency. Understanding these principles is vital for engineers and technicians alike, as they work to optimize the functionality of these critical components in their systems.

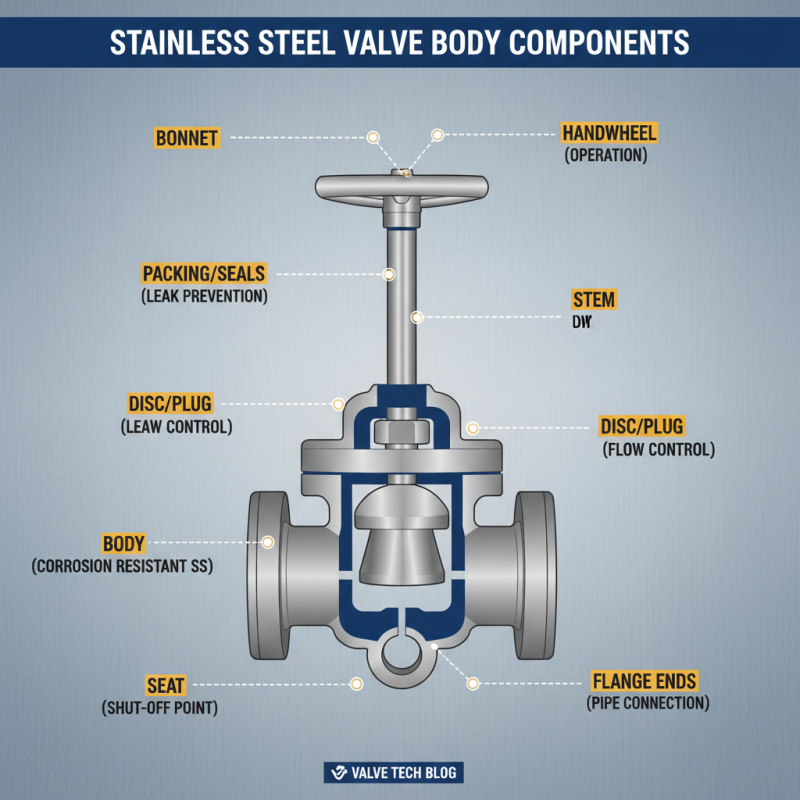

Understanding the components of a stainless valve body is crucial for anyone involved in maintenance or operation. A stainless valve body typically comprises several key elements, including the body, bonnet, stem, and sealing components. The body itself is crafted from stainless steel, which provides excellent resistance to corrosion and enhances durability under varying temperatures and pressures. This material is essential for applications involving fluids that might otherwise degrade lesser metals, ensuring the integrity of the valve over extended periods.

The bonnet houses the valve's internal mechanisms and is where many of the valve's operational components emerge. This is often where the stem, responsible for the valve’s opening and closing function, is located. Proper lubrication of the stem and regular inspection of the sealing components can prevent leaks and ensure smooth operation. When maintaining a stainless valve body, it is important to inspect these components frequently, as wear and degradation can occur over time, potentially leading to significant performance issues. Understanding these essential elements allows for better maintenance practices, ultimately leading to improved longevity and operational efficiency of the valve system.

Stainless valves are essential components in various industrial applications, and understanding the common causes of wear and tear is crucial for maintaining their longevity and performance. One primary factor contributing to wear in stainless valves is corrosion, which can occur even with stainless steels due to exposure to harsh chemicals or high salinity environments. Over time, this corrosion can lead to pitting, which compromises the valve's integrity and function.

Another significant contributor to wear is mechanical fatigue. Repeated cycling of valves can cause stress on seals and connections, leading to leaks or reduced efficiency. Additionally, improper installation or misalignment can increase the wear rate, as the valve components may not engage smoothly during operation. Regular inspections and maintenance cycles can help identify these issues early, allowing operators to take corrective actions before they result in extensive damage.

Routine maintenance is crucial for ensuring the longevity and optimal performance of stainless valve bodies. Regular inspection should be a foundational practice, where wear and tear, surface corrosion, or signs of damage are evaluated. Monitoring these factors can help in identifying potential issues before they escalate, reducing the risk of costly repairs or replacements. Utilizing appropriate cleaning solutions to remove dirt and buildup is also essential, as contaminants can affect valve operation and efficiency.

Another important aspect of maintenance involves lubrication. Regularly applying suitable lubricants can minimize friction and wear on moving parts, ensuring smooth operation. It is also vital to check seals and gaskets frequently, as these components can degrade over time, leading to leaks and reduced performance. Establishing a routine maintenance schedule that includes these practices will not only extend the lifespan of stainless valve bodies but also enhance their reliability in various applications.

When it comes to maintaining stainless valve bodies, employing the best cleaning methods is crucial for ensuring optimal performance and longevity. A recent industry report indicates that improper cleaning techniques can lead to a significant reduction in valve efficiency, with data suggesting that neglecting regular maintenance can decrease operational performance by up to 30% over time. Therefore, it is essential to adopt effective cleaning strategies that preserve the integrity of stainless steel while removing contaminants and preventing corrosion.

One of the most effective methods for cleaning stainless valve bodies involves the use of aqueous cleaning solutions that are specifically designed to tackle oils, dirt, and other contaminants without causing damage to the surface. This approach is supported by research showing that using low-pH cleaning agents can be beneficial, as they effectively dissolve organic deposits without compromising the stainless steel’s protective oxide layer.

Additionally, ultrasonic cleaning has emerged as a leading method in the industry, leveraging high-frequency sound waves to agitate cleaning solutions and penetrate hard-to-reach areas, thus ensuring a thorough clean and enhancing the overall reliability of the valve body.

Incorporating regular inspections into the maintenance routine further emphasizes the importance of proactive care. Many industry experts agree that implementing a cleaning schedule every three to six months can significantly extend the service life of stainless valve bodies. Furthermore, regular assessments allow for the timely identification of wear or potential issues, ultimately preventing costly downtimes in industrial applications. By consistently applying these cleaning techniques and maintenance practices, businesses can ensure the longevity and performance of their stainless valve components.

When it comes to maintaining the efficiency and lifespan of

stainless valve bodies, recognizing the signs that indicate a potential replacement is essential. Common indicators of wear and potential failure include visible corrosion, unusual vibrations, and leaking fluids. According to industry reports, approximately

30% of valve failures are attributed to poor maintenance practices, underscoring the need for regular inspections and prompt action when these signs are observed.

To enhance the durability and performance of stainless valve bodies, it's advisable to implement a rigorous maintenance routine. Regularly check for signs of wear, particularly around the seals and joints, and ensure that valve operators are trained to recognize abnormal behaviors. Additionally, utilizing protective coatings can mitigate corrosion risks, significantly prolonging the life of the valve body.

To enhance the durability and performance of stainless valve bodies, it's advisable to implement a rigorous maintenance routine. Regularly check for signs of wear, particularly around the seals and joints, and ensure that valve operators are trained to recognize abnormal behaviors. Additionally, utilizing protective coatings can mitigate corrosion risks, significantly prolonging the life of the valve body.

Another effective maintenance tip involves monitoring operational conditions closely. Studies indicate that valves operating outside their design parameters endure accelerated wear, leading to early replacement needs. By maintaining optimal pressure and temperature conditions, as well as adhering to manufacturer guidelines, organizations can minimize the risk of premature failures.

Implementing such best practices not only ensures valve longevity but also enhances overall system performance, contributing to more reliable operations.

Another effective maintenance tip involves monitoring operational conditions closely. Studies indicate that valves operating outside their design parameters endure accelerated wear, leading to early replacement needs. By maintaining optimal pressure and temperature conditions, as well as adhering to manufacturer guidelines, organizations can minimize the risk of premature failures.

Implementing such best practices not only ensures valve longevity but also enhances overall system performance, contributing to more reliable operations.