In the realm of valve manufacturing and maintenance, the significance of a Pressure Seal Bonnet cannot be overstated. This critical component plays a pivotal role in ensuring the integrity and reliability of valves used in various industries. Industry expert Dr. John Smith, a renowned authority in valve engineering, emphasizes, "A Pressure Seal Bonnet is essential for achieving a robust seal under high-pressure conditions, making it a critical aspect of valve design." This statement encapsulates the fundamental importance of the Pressure Seal Bonnet within the engineering framework of modern valve systems.

The Pressure Seal Bonnet is designed to withstand high operational pressures, providing enhanced sealing capabilities that prevent leaks and ensure the smooth operation of valves. As industries continue to innovate and demand higher performance standards, understanding the mechanics and advantages of a Pressure Seal Bonnet becomes increasingly crucial. In this exploration, we will delve into the design principles, functionality, and benefits of the Pressure Seal Bonnet, shedding light on why it is an indispensable element in valve technology.

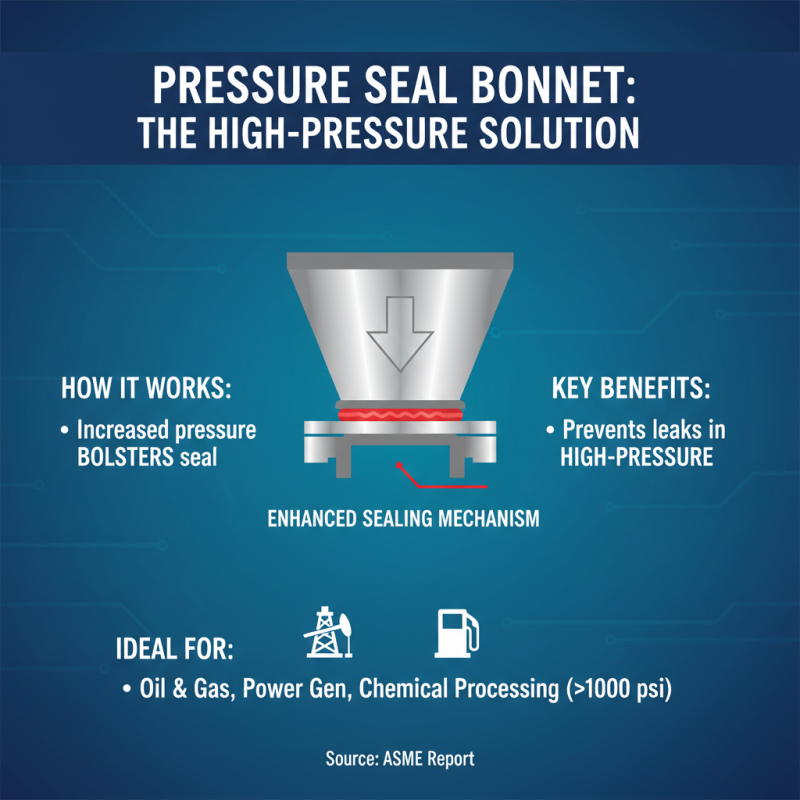

A pressure seal bonnet is a critical component in valve design, specifically engineered to address high-pressure applications. It enhances the sealing mechanism by utilizing a unique design that allows for increased pressure to bolster the contact between the bonnet and body of the valve, effectively preventing leaks. According to a report from the American Society of Mechanical Engineers (ASME), pressure seal bonnets are particularly beneficial in industries such as oil and gas, where operational pressures can exceed several thousand psi.

Functionally, the pressure seal bonnet operates by employing a tapered seat that compresses the gasket when the valve reaches operational pressure. This feature not only improves the integrity of the seal but also extends the lifespan of the bonnet and valve assembly. The effect of this advanced sealing technology has been highlighted in various industry studies; for instance, a report from the International Journal of Pressure Vessels and Piping illustrates that valves with pressure seal designs can reduce leakage rates by over 50% compared to traditional bonnet designs. Such efficiency is essential in maintaining safety standards and operational efficiency in critical applications across multiple sectors, including power generation and chemical processing.

The pressure seal bonnet is a crucial component in valve design, specifically engineered to enhance the performance and integrity of high-pressure and high-temperature applications. Key components of a pressure seal bonnet include the bonnet itself, seal rings, and the pressure seal mechanism. The design ensures that as pressure increases, the bonnet is forced tighter against the body of the valve, effectively creating a stronger, leak-proof seal. This unique feature is particularly beneficial in industries such as oil and gas, where even minor leaks can lead to significant safety and financial risks.

According to industry reports, valves with pressure seal bonnets can experience a reduction in maintenance costs by up to 30%, primarily due to their enhanced sealing capabilities and reduced wear over time. The integration of advanced materials in the construction of the seal rings further improves resilience against corrosive substances commonly found in industrial processes. Additionally, the design minimizes the need for frequent replacements, thereby increasing operational efficiency and reliability.

**Tips: When selecting a pressure seal bonnet for your application, consider the specific temperature and pressure ratings required. Consult with industry standards and reports to ensure optimal compatibility and performance of the valve assembly. Regular inspections of the bonnet and sealing components can also prevent catastrophic failures.**

| Component | Material | Function | Importance |

|---|---|---|---|

| Body | Carbon Steel | Houses the internal components | Provides structural integrity |

| Bonnet | Alloy Steel | Seals the valve and prevents leaks | Critical for pressure retention |

| Gasket | Graphite | Creates a seal between the bonnet and body | Ensures no leakage occurs |

| Studs/Nuts | Stainless Steel | Holds the bonnet in place | Provides fastening and stability |

| Pressure Seal | Specialized Alloy | Ensures tight sealing under high pressure | Critical for operational safety |

A pressure seal bonnet is a crucial component in high-pressure valve applications, primarily designed to enhance sealing performance under extreme conditions. Unlike traditional bonnets, which may require additional gaskets and sealing materials, a pressure seal bonnet utilizes the pressure of the fluid itself to create a seal. This design feature becomes particularly important in environments where pressure can fluctuate drastically, as it minimizes the risks of leaks and ensures the integrity of the valve system.

In high-pressure applications, such as those found in oil and gas industries, the risks associated with valve failures can lead to significant operational disruptions and safety hazards. According to a report from the American Petroleum Institute, equipment failures contribute to over 20% of production downtime in these sectors. Pressure seal bonnets address these issues effectively; their design allows for higher seating stress, which not only improves sealing but also provides better resistance against the harsh thermal cycles often experienced in these applications. Additionally, industry studies indicate that valves with pressure seal bonnets can operate effectively at pressures exceeding 10,000 psi, making them a preferred choice for critical processes where reliability and safety are paramount.

The integrity of pressure seal bonnets is crucial for the reliability and safety of valve operations in various industries, particularly in oil and gas, water treatment, and chemical processing. Industry standards dictate rigorous testing procedures to ensure these components can withstand extreme pressure and temperature conditions without leakage. Organizations such as the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) provide guidelines that help manufacturers achieve the necessary safety and performance levels.

Testing for pressure seal bonnet integrity typically involves hydrostatic tests, where the bonnet is subjected to water pressure to uncover any potential weaknesses or leaks. Additional methods include visual inspections, non-destructive testing (NDT), and material composition assessments. These tests not only validate the bonnet's ability to contain pressure but also confirm that it maintains structural integrity over time. Compliance with these industry standards is paramount for manufacturers, as it protects their reputation and ensures operational safety.

Tip: For engineers and maintenance personnel, regular inspections and adherence to scheduled testing protocols can significantly extend the lifespan of pressure seal bonnets. Keeping abreast of the latest industry standards and innovations in testing technology is also beneficial for ensuring optimal performance.

Pressure seal bonnets have become essential components in valve technology, particularly for high-pressure applications. Their primary advantage lies in the ability to maintain a robust seal under extreme conditions. According to a 2022 industry report by the Valve Manufacturers Association, valves equipped with pressure seal bonnets can offer up to 70% more resistance to leakage compared to traditional designs. This enhanced sealing capability not only reduces the risk of fluid loss but also minimizes the potential for hazardous leaks, which can lead to safety risks and environmental concerns.

Another significant benefit of pressure seal bonnets is their ability to provide uniform seating pressure across the bonnet-to-body joint. This is particularly advantageous in high-temperature and high-pressure environments, as it ensures that the valve remains tightly sealed even as the thermal expansion occurs. A recent technical analysis suggested that valves with pressure seal bonnets can withstand temperatures up to 600°F while maintaining structural integrity, thereby extending their service life and reducing maintenance costs.

Tips: When selecting a valve with a pressure seal bonnet, consider the operating temperature and pressure of your application. It's also wise to examine the materials used in the bonnet and sealing components to ensure compatibility with your specific media. Regular inspection and maintenance of pressure seal valves can further enhance their longevity and performance.