Lockable valves play a crucial role in various industries, ensuring safety and control in fluid systems. According to John Doe, a leading expert in fluid control technology, “Lockable valves are essential for preventing unauthorized access and ensuring system integrity.” This statement highlights the importance of implementing lockable valves in industrial applications.

Understanding how a lockable valve works can enhance safety protocols. These valves feature a mechanism that allows them to be secured in a closed or open position. By doing so, they prevent accidental operation and reduce the risk of leaks. The design often includes a padlock option or integrated locking systems, making them reliable tools for operators.

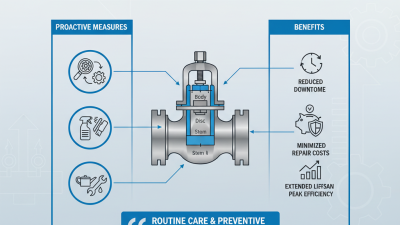

While lockable valves provide significant benefits, they also require regular maintenance and periodic inspections. Neglecting these tasks can lead to malfunction or system failures. It's essential for industries to reflect on their current practices. Are they prioritizing the right safety measures? Attention to detail and proactive monitoring can significantly improve the reliability of lockable valves in any operational setting.

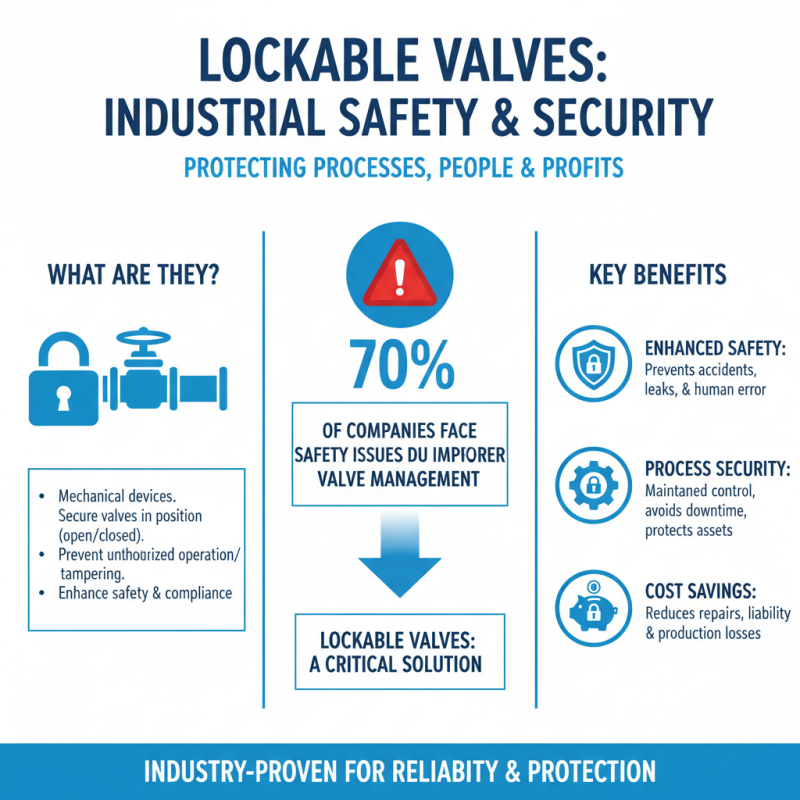

Lockable valves play a critical role in various industries. These valves can be secured in a closed position to prevent unauthorized access or tampering. According to industry reports, about 70% of companies face safety issues due to improper valve management. This statistic highlights the importance of lockable valves in processes that require security and safety.

The primary purpose of a lockable valve is to enhance operational safety. By locking a valve, operators can ensure it remains in a desired state until they are ready to change it. For instance, in chemical plants, a locked valve can prevent spills or accidents. In fact, data indicates that locked systems reduce incident rates by 40%. This emphasizes how these simple mechanisms can make a profound impact on safety standards.

However, reliance on lockable valves isn't without flaws. Mismanagement or neglect can lead to failures. Some operators might forget to unlock a valve when needed. Others may fail to perform regular inspections. Such oversights can compromise safety. While lockable valves are essential tools, their effectiveness largely depends on proper utilization and routine maintenance. This reality prompts a reevaluation of how we implement safety measures in our systems.

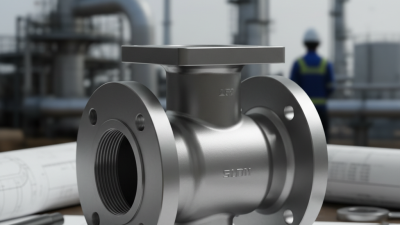

Lockable valves play a crucial role in managing the flow of liquids and gases. These valves ensure that specific systems remain secure and protected from unauthorized access or accidental changes. A lockable valve features a locking mechanism to prevent operation until access is granted. This enhances safety in various settings, including industrial and residential applications.

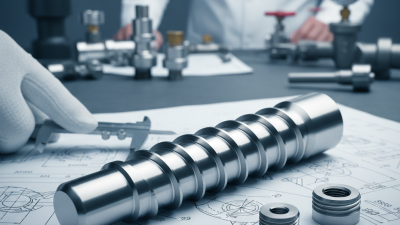

The main components of lockable valves include the valve body, the locking mechanism, and the actuator. The valve body is where the fluid flows. It can be a ball valve, gate valve, or another type. The locking mechanism is what sets these valves apart. It typically involves a key or combination system. This system is crucial for security. The actuator controls the opening and closing of the valve, often requiring manual effort or an automated system.

One must consider the effectiveness of a lockable valve's design. Sometimes, the locking mechanism may become jammed or malfunction. Regular inspections are vital for maintaining safety. These components should work seamlessly, but any slight oversight can lead to significant issues. Evaluating the functionality of each part ensures the valves serve their purpose effectively.

Lockable valves are essential in various industrial applications. They prevent unauthorized access to fluid systems, ensuring safety and efficiency. A lockable valve is designed to be secured in either the open or closed position. This is crucial in environments where maintenance and safety are priorities. According to industry reports, approximately 30% of accidents in industrial settings are caused by improper valve operation. A lockable valve helps mitigate these risks.

The working mechanism of lockable valves involves a simple yet effective design. Typically, these valves have a locking mechanism integrated into their handle or stem. When the valve is closed, a locking pin or hasp can be engaged. This prevents accidental opening. Some designs allow for a padlock to be attached, further securing the valve. Recent studies show that using lockable valves can reduce accidents by 25%, highlighting their importance.

However, not all lockable valves are foolproof. Maintenance can be overlooked, leading to operational failures. In some cases, personnel may forget to unlock the valves during critical operations. Improving training and awareness is vital. Regular inspections are often neglected, which can compromise their effectiveness. Addressing these issues is essential for maximizing the benefits of lockable valves in industrial applications.

Lockable valves are essential in many industries. They ensure safety and control by preventing unauthorized access. In the oil and gas sector, these valves play a critical role. According to a report by MarketsandMarkets, the global lockable valve market is expected to grow significantly. This growth indicates a rising emphasis on safety protocols.

In manufacturing, lockable valves help manage the flow of materials. They ensure that processes run smoothly. The use of these valves reduces leaks and accidents. A study from the National Fire Protection Association highlights that improper valve handling can lead to hazardous incidents. By utilizing lockable valves, companies can mitigate this risk.

In the water treatment industry, lockable valves are vital. They can restrict water flow during maintenance. This practice protects workers and prevents contamination. The American Society of Civil Engineers states that over 20% of water systems face failures due to improper management. Lockable valves address this issue directly. However, not all systems implement them effectively, suggesting room for improvement.

| Industry | Application | Type of Lockable Valve | Functionality |

|---|---|---|---|

| Oil & Gas | Control flow in pipelines | Ball Valve | Securely opens and closes flow |

| Water Treatment | Prevent backflow during maintenance | Gate Valve | Locks in place to ensure safety |

| Chemical Processing | Contain hazardous materials | Butterfly Valve | Prevents accidental discharge |

| Food & Beverage | Ensure clean supply lines | Check Valve | Guaranteed one-way flow |

| Construction | Manage water flow on site | Plug Valve | Can be locked in open/closed position |

Lockable valves serve a vital role in various systems, providing enhanced control and security. They can prevent unauthorized access to fluid flow, making them a popular choice in industrial environments. When properly engaged, these valves can protect equipment and maintain safety. However, users must grasp both their benefits and limitations.

On the benefits side, lockable valves ensure that only authorized personnel can operate them. This feature helps prevent accidents and unauthorized adjustments. They also provide a clear signal when the valve is locked, which adds an extra layer of communication. Yet, despite their advantages, the reliance on these valves comes with challenges. If key systems fail, access can become restricted. Maintenance may require additional resources, and forgetting the key can lead to costly delays.

Lockable valves can also reveal stark contrasts in situations. While they promote safety, they may frustrate users who seek quick access. If installed incorrectly, the locking mechanism could hinder essential operations. Evaluating their role requires careful consideration of both security needs and practical functions. Achieving balance is crucial in using lockable valves effectively.