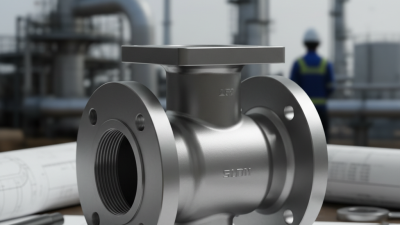

Lockable valves play a crucial role in many industries. They offer safety and control, ensuring that fluid flow is managed effectively. However, many users overlook their potential. This can lead to inefficiencies and safety risks. Understanding how to use lockable valves correctly is essential.

Effective use requires knowledge and practical tips. For instance, proper installation is key. Ensure that valves are correctly aligned and secured. Regular maintenance is also vital. This means checking for wear and tear, which can compromise functionality.

Many users forget the importance of operator training. It's not enough to install a lockable valve; everyone must know how to use it. Sometimes, a lack of training leads to misuse. This can result in leaks or equipment damage. Reflecting on these issues is necessary for improvement. By implementing best practices, users can maximize the benefits of lockable valves.

Lockable valves are essential components in various industries, from water management to chemical processing. To maximize their effectiveness, understanding their critical features is vital. Key features include robust locking mechanisms that prevent unauthorized access and leakage. A quality lockable valve should have a smooth operation for easy use, while its materials must withstand corrosion. Data indicates that improper valve use can increase leak occurrences by 30%, highlighting the need for optimal design.

When effectively utilizing lockable valves, remember these tips. Regular maintenance can prevent malfunctioning. Schedule inspections every six months to ensure valves remain functional. Always verify the locking mechanism before use. A framework of clear operational procedures is crucial. Set guidelines for users to follow carefully. This might require a bit of additional training.

Moreover, consider the specific application of the valve. It's important to match the valve type with its intended use. Some may require higher pressure tolerance, while others must withstand harsh chemicals. Documenting these specifications helps in selecting the right valve. Keeping detailed records can minimize potential misuse and promote accountability. When all factors align, lockable valves can dramatically enhance safety and efficiency in operations.

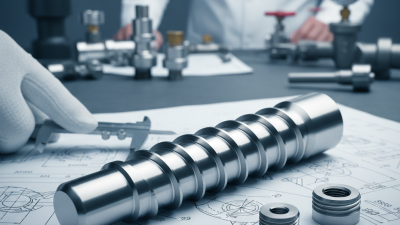

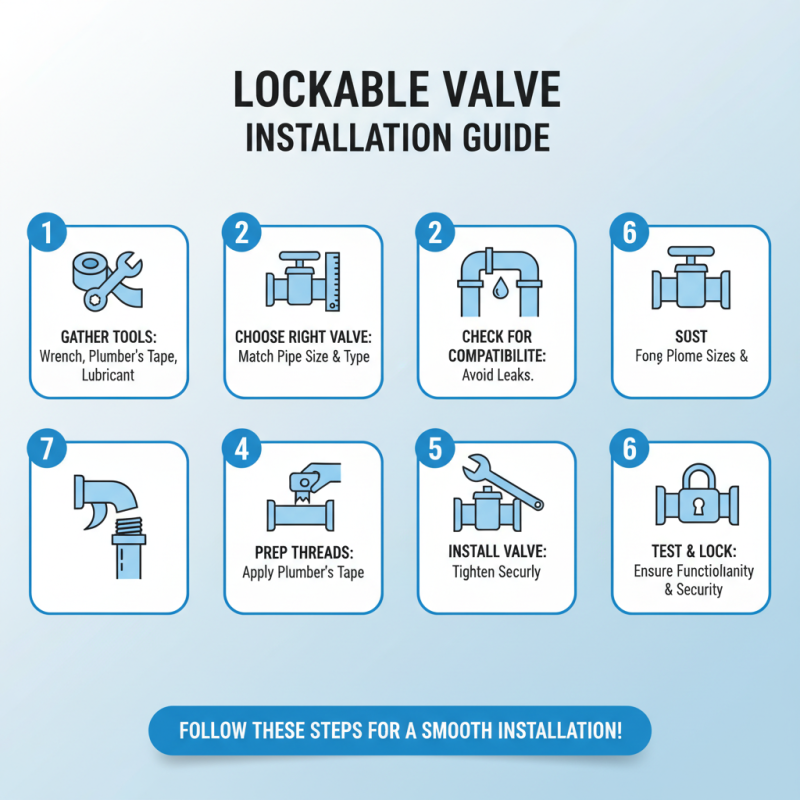

Installing lockable valves can be straightforward if you follow a step-by-step approach. Begin by gathering your tools. You'll need a wrench, tape, and lubricant. Make sure you have the right valve for your needs. Ensure it matches the pipe size. Take your time with this step. A mismatch can lead to leaks.

Once you have everything ready, shut off the water supply. This step is crucial to prevent accidents. After that, drain any residual water in the pipes. Next, use the wrench to remove the existing valve. If it feels stuck, apply some lubricant and wait a bit. Do not force it; you might damage the pipes.

Now, prepare the installation site. Clean the threads on the pipes. Apply some tape to ensure a tight seal. Carefully install the new lockable valve, tightening it securely. It's easy to overlook tightness. After everything is in place, turn the water supply back on slowly. Watch for leaks. If you find any, revisit your installation steps. Mistakes happen. Reflect on your work and learn from it.

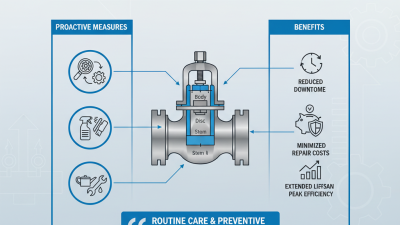

Lockable valves play a crucial role in ensuring system safety and operational efficiency. Proper maintenance is essential for these devices to perform effectively. Regular inspections can prevent failures that might lead to costly downtime. According to industry reports, effective maintenance can enhance valve lifespan by up to 30%.

One tip for maintaining lockable valves is to establish a routine inspection schedule. Frequent checks help identify wear and tear. It is vital to clean the valve regularly to prevent buildup. Dirt can cause valves to seize or operate inefficiently. Additionally, check the locking mechanism for any signs of damage. Prompt repairs can avoid more significant issues later.

Ensure lubrication of moving parts. Proper lubrication minimizes friction and overheating. A study indicates that well-lubricated valves reduce energy consumption by 20%. It is also important to monitor any leakage. Unexpected leaks can compromise safety. Regular monitoring helps maintain peace of mind and operational integrity. Sometimes, refurbishment might be necessary. However, implementing these practices can enhance both reliability and performance.

When using lockable valves, safety is paramount. These devices prevent accidental flow changes, but they require careful handling. Personnel must be trained on their operation. An overlooked detail can lead to hazardous situations. When locking valves, ensure everyone is aware. Communication is key in preventing misunderstandings.

Inspect the lockable valves regularly. Wear and tear can compromise their effectiveness. If a valve shows signs of damage, it should be reported immediately. Immediate action can avoid potential disasters. Additionally, always use the correct lock type for the valve. Mixing locks can create confusion.

Consider environmental factors. Equipment near corrosive materials may degrade faster. Keep an eye on the conditions surrounding your operation site. Workers should report any irregularities. Regular training updates are essential. They reinforce safe practices and address any new concerns. Recognizing the importance of vigilance can make a significant difference in operational safety.

| Tip Number | Tip Description | Safety Consideration |

|---|---|---|

| 1 | Ensure proper training on lockable valve operation. | Reduces risk of accidents due to improper use. |

| 2 | Regular maintenance and inspection of valves. | Identifies potential failures before they occur. |

| 3 | Use color-coded locks for easy identification. | Enhances visibility and reduces misuse. |

| 4 | Establish clear procedures for locking and unlocking. | Mitigates confusion and increases safety compliance. |

| 5 | Document and label all lockable valve locations. | Ensures quick access during emergencies. |

| 6 | Engage all employees in safety discussions regarding valves. | Fosters a culture of safety across operations. |

| 7 | Incorporate lockable valves in risk assessments. | Identifies risks associated with their use. |

| 8 | Utilize safety alerts and tag-out systems. | Prevents accidental operation during maintenance. |

| 9 | Conduct regular training refreshers on valve use. | Keeps safety information up to date. |

| 10 | Ensure valve locking mechanisms are robust and reliable. | Prevents tampering or accidental disengagement. |

Lockable valves are crucial for safely controlling fluid flow in various systems. However, they may encounter common issues that hinder their performance. According to industry reports, about 30% of valve malfunctions stem from improper installation. Ensuring precise installation can mitigate substantial downtime and maintenance costs.

One common issue is valve leakage. Data shows that nearly 15% of lockable valves face leakage problems due to worn seals or improper closing mechanisms. Regular checks on these seals can prevent significant losses. Additionally, operators should be aware that environmental factors, such as temperature changes, can affect the seal's integrity. This creates a potential for leaks to occur.

Another consideration is operator training. Often, staff may not fully understand the valve’s locking mechanism, leading to mishandling. It's reported that 20% of operational failures are due to human error. Providing thorough training can improve confidence and efficiency among staff. Regular maintenance schedules should also be established to ensure that all components function properly. By addressing these issues, organizations can enhance the reliability of lockable valves and prevent operational disruptions.