When embarking on your next project, selecting the appropriate materials is crucial to ensure durability and performance. Among the various options available, the Stainless Bonnet stands out as a versatile and reliable choice for an array of applications. This specialized component not only enhances aesthetic appeal but also provides exceptional resistance to corrosion and wear, making it an ideal fit for both residential and industrial settings.

Understanding the specific requirements of your project is essential when choosing the right Stainless Bonnet. Factors such as size, shape, and finish can significantly impact functionality and visual integration with other elements. Additionally, it’s important to consider the environmental conditions the bonnet will face, as this will influence the selection process and ultimately determine the longevity and efficiency of your project.

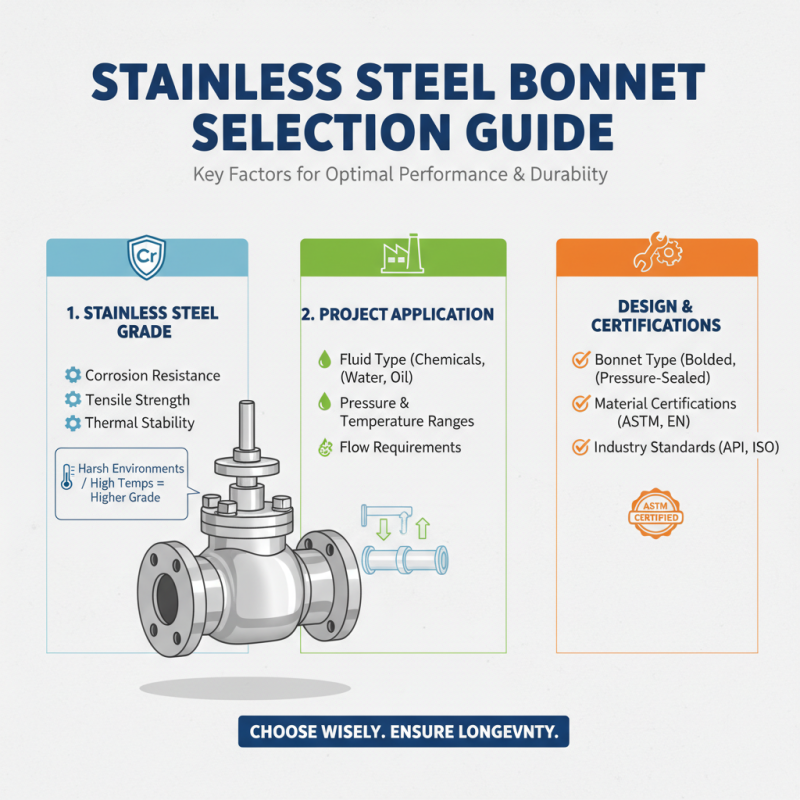

In this guide, we will explore key considerations and tips for selecting the right Stainless Bonnet, highlighting the importance of material properties, design choices, and compatibility with other components. Whether you are a seasoned professional or a DIY enthusiast, making an informed decision will ensure the success and durability of your project.

When it comes to selecting a stainless bonnet for your next project, it's essential to understand their fundamental characteristics and applications. Stainless bonnets are designed to provide an effective seal on valves, fittings, and other components used in various industries such as plumbing, automotive, and oil and gas. Their durability against corrosion and high temperatures makes them a preferred choice for a wide range of environments.

One of the key tips for choosing the right stainless bonnet is to consider the specific application requirements. For example, if you are working in a high-pressure environment, opting for a bonnet that can withstand these conditions is crucial. Additionally, the finish and grade of stainless steel can significantly affect the performance and longevity of the bonnet, so it's important to match these specifications with your project's needs.

Another important factor is the compatibility of the bonnet with other materials in your system. Using the right gasket and ensuring the overall assembly height is correct can greatly enhance performance and prevent leaks. Always keep in mind that proper installation and maintenance will not only extend the lifespan of your stainless bonnet but also ensure the safety and efficiency of your entire project.

When selecting the right stainless bonnet for your next project, several key factors should be taken into account to ensure optimal performance and durability. First, consider the type of stainless steel used in the bonnet’s construction. Different grades of stainless steel offer varying levels of corrosion resistance, tensile strength, and thermal stability. For projects that involve exposure to harsh environments or high temperatures, opting for a higher-grade stainless steel may be beneficial to prolong the lifespan of the bonnet.

Another important factor is the size and fit of the stainless bonnet. It is crucial to match the bonnet dimensions with the specific application requirements to prevent leaks or failures in the system. Accurate measurements and compatibility with existing components will help maintain the system's integrity. Additionally, the design features such as sealing mechanisms and support options should be evaluated based on the project’s needs to enhance efficiency and usability. Taking these considerations into account will help ensure that the selected stainless bonnet meets the project specifications and performs reliably over time.

When selecting a stainless bonnet for your project, it is essential to understand the different types of stainless steels available, as each possesses unique properties suited for various applications. The most commonly used stainless steel types are 304 and 316.

Type 304 stainless steel is known for its excellent corrosion resistance and is often suitable for general-purpose applications. It is easy to fabricate and weld, making it a popular choice in the food and beverage industry where hygiene is paramount.

On the other hand, type 316 stainless steel is recognized for its enhanced corrosion resistance, particularly against chlorides and other aggressive environments. This makes it an ideal choice for marine and chemical processing applications where durability and longevity are crucial. Additionally, the higher nickel and molybdenum content of 316 stainless steel provides better resistance to pitting and crevice corrosion, adding to its reliability in harsh conditions. When choosing the right stainless bonnet, considering these stainless steel types and their specific advantages will ensure that your project is equipped with the best materials for its requirements.

When selecting a stainless bonnet for your project, the first step is to assess both the size and compatibility with existing equipment or systems. The dimensions of the bonnet must match the specifications required for proper fitment. A bonnet that is too large or small can lead to inefficiencies or installation issues, compromising the overall effectiveness of your project. Measuring the aperture and ensuring that the flange dimensions align with your system is critical. Additionally, consider the operating environment; pressure and temperature ratings should align with the bonnet’s capabilities.

Compatibility extends beyond size; it's also essential to consider materials and design. Stainless bonnets come in various grades, each possessing unique corrosion resistance and strength characteristics. Checking the compatibility of the stainless steel grade with the other materials in your system can prevent galvanic corrosion and enhance durability. Evaluate the intended use and any specific environmental conditions, ensuring that the material will perform effectively without degradation over time. By paying close attention to these factors, you can ensure that your stainless bonnet will function reliably within your project, ultimately leading to a successful outcome.

When it comes to choosing the right stainless bonnet for your project,

understanding how to maintain it is crucial for longevity. Stainless steel is renowned for its durability and

resistance to corrosion, but proper care and maintenance are key to ensuring its performance over time.

One effective maintenance tip is regular cleaning. Depending on the environment, stainless bonnets can

accumulate dirt, grease, or even water spots.

Using a mild detergent with warm water and a soft cloth can help keep the surface clean without scratching it.

Additionally, avoid using harsh chemicals that could damage the finish.

For stubborn stains or residues, application of a specialized stainless steel cleaner can restore its shine.

Another important aspect is monitoring for any signs of wear or damage. Regular inspections can help you catch

issues early, such as rust or deformation, which may require immediate attention. When storing stainless bonnets,

ensure they are kept in a dry place to prevent moisture accumulation, which can lead to corrosion.

Finally, consider applying a protective coating suitable for stainless steel, especially if the bonnet is exposed

to harsh conditions, to enhance its lifespan and maintain its aesthetic appeal.