When it comes to plumbing, the selection of appropriate components is essential for achieving system efficiency and reliability. Union valves are crucial elements that allow for easy disassembly and maintenance of piping systems, making them a preferred choice for many professionals. As plumbing expert John Smith once noted, "The right union valve not only simplifies repairs but also enhances the longevity of your plumbing infrastructure."

In navigating the varied options available in the market, understanding what constitutes the right union valves for specific plumbing needs is paramount. Factors such as the material, size, and pressure ratings play a significant role in ensuring optimal performance. Whether you are a seasoned plumber or a homeowner tackling a DIY project, making informed decisions about union valves can save both time and costs in the long run. This guide aims to shed light on the critical aspects to consider when choosing union valves, ensuring that you select the best options for your plumbing requirements.

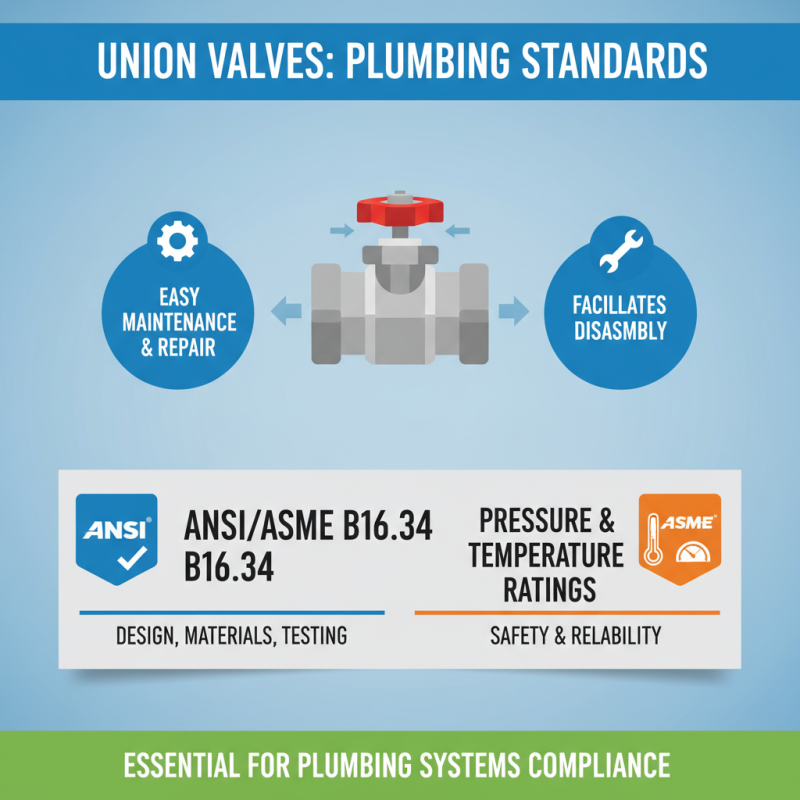

Union valves play a crucial role in plumbing systems by allowing for easy connections and disconnections between piping sections. These valves are designed to facilitate maintenance and repairs without the need to dismantle entire piping systems. By providing a simple way to separate sections of piping, union valves help to reduce downtime during plumbing work, making them an essential component for both residential and commercial plumbing applications.

Understanding the importance of union valves goes beyond their convenience. They contribute to the overall efficiency and integrity of the plumbing system. When installed correctly, union valves help to ensure a tight seal and maintain proper flow control, minimizing leaks and potential damage. Additionally, they offer flexibility for future alterations or expansions of the plumbing infrastructure, making them a wise investment for long-term plumbing solutions. Thus, selecting the appropriate union valves for specific plumbing needs can significantly enhance system reliability and performance.

When selecting union valves for plumbing systems, several key factors should be considered to ensure optimal performance and longevity. One primary consideration is the material of the valve. Common materials include brass, stainless steel, and PVC, each with its own advantages. For example, a report by the American Society of Plumbing Engineers highlights that brass valves provide excellent durability and resistance to corrosion, making them suitable for hot and cold water applications. In contrast, PVC is often used in residential plumbing for its lightweight and cost-effective properties, particularly in drainage systems.

Another critical factor is the valve size and connection type. According to a study from the International Association of Plumbing and Mechanical Officials, improper sizing can lead to decreased flow rates and increased pressure drops in the system. It’s important to meticulously match the union valve size with existing piping to maintain system efficiency. Additionally, the type of connection—whether threaded, soldered, or glue joints—must be compatible with the overall plumbing design to facilitate straightforward installation and maintenance. Failure to consider these aspects can result in leaks and system failures, underscoring the necessity of thorough planning in valve selection.

Union valves are essential components in plumbing systems, facilitating the connection between different piping materials and enabling repairs without the need for cutting pipes. There are several types of union valves, each tailored for specific applications within residential and commercial plumbing. One common type is the threaded union valve, which allows for easy connection and disconnection of pipes using threaded fittings. This type is often used in areas where maintenance is frequent, such as water heaters or filtration systems.

Another type is the solder union valve, best suited for copper piping. This valve creates a permanent and leak-proof seal through a soldering process, ensuring a robust connection. Solder union valves are frequently employed in high-temperature applications, such as hot water lines. Lastly, there are flange union valves, which are advantageous for larger piping systems and provide a strong connection through bolts and flanges, making them ideal for applications where pipes may require more support and stability.

In addition to these types, it is crucial to consider the application requirements such as pressure ratings and temperature limits when choosing the appropriate union valve. Selecting the right valve type not only enhances the overall efficiency of the plumbing system but also prolongs its lifespan by minimizing the risk of leaks and failures. Understanding the characteristics and applications of each union valve type ensures that plumbing systems operate smoothly and effectively.

When selecting union valves for plumbing systems, one of the most critical considerations is the choice of material. Common materials include brass, stainless steel, and plastic, each with its own set of advantages and disadvantages. Brass is renowned for its durability and corrosion resistance, making it suitable for a wide range of applications, from residential plumbing to industrial settings. However, it can be more expensive than other options and may be prone to dezincification if not properly protected.

On the other hand, stainless steel is another popular choice, known for its strength and resistance to rust and corrosion. It is ideal for high-pressure applications and environments where chemicals are present. However, stainless steel can be heavy and more challenging to work with compared to lighter materials. For more budget-conscious projects or applications where weight is a concern, plastic union valves made from PVC or CPVC can be a valuable option. They are lightweight, resistant to many chemicals, and highly cost-effective. Nonetheless, they may not hold up well in extreme temperatures or pressures, limiting their use in demanding installations. By understanding the pros and cons of these material options, homeowners and professionals can make informed decisions that best suit their plumbing needs.

| Material | Pros | Cons | Typical Applications |

|---|---|---|---|

| Brass | Durable, resistant to corrosion, excellent for high-pressure applications | Can be expensive, may require special tools for installation | Water, gas lines, and hydraulic systems |

| PVC | Lightweight, low cost, resistant to rust and corrosion | Not suitable for high temperatures, can become brittle over time | Drainage systems, irrigation |

| Stainless Steel | Highly resistant to corrosion and staining, long lifespan | Higher cost compared to other options, can be heavy | Food processing, chemical industries, plumbing |

| Bronze | Excellent for marine environments, strong and durable | Can be more expensive than brass, not as commonly available | Marine applications, freshwater systems |

When selecting union valves for plumbing systems, it's essential to consider the industry standards and regulations that govern their use. Union valves are critical components in plumbing, as they facilitate easy disassembly of pipelines for maintenance and repairs without having to remove the entire assembly. The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) provide guidelines that ensure the safety and reliability of these valves. Specifically, ANSI/ASME B16.34 outlines the requirements for design, materials, and testing, specifying pressure and temperature ratings that ensure the valves can withstand varying conditions in plumbing applications.

To ensure compliance and effectiveness, plumbers should refer to the National Plumbing Code (NPC) and the International Plumbing Code (IPC), which detail specifications for valve installation and durability. These codes emphasize the importance of selecting materials that resist corrosion and environmental degradation, ultimately prolonging the life of the plumbing system. Additionally, the United States Department of Energy (DOE) suggests identifying union valves that meet or exceed energy efficiency requirements, potentially enhancing overall system performance while reducing costs.

Tips: When evaluating union valves, always check for certifications that demonstrate compliance with industry standards. Look for valves made from durable materials like brass or stainless steel, which are known for their long-lasting properties and resistance to corrosion. Finally, consider the valve size and compatibility with existing piping to ensure a proper fit, minimizing the risk of leaks and improving system integrity.