Choosing the right stainless valve stem for your specific needs can be a daunting task. Industry expert Dr. John Steele remarks, “Selecting a proper stainless valve stem is crucial for optimal performance and longevity.” This statement reflects the importance of making an informed choice.

In a market full of options, understanding the features of stainless valve stems is essential. Different applications require different specifications. Factors such as size, material grade, and design impact performance greatly.

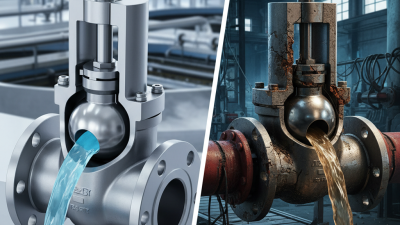

Some may overlook these details, leading to costly mistakes. For instance, using an inadequate valve stem can cause leaks or mechanical failures. Always consider your requirements carefully. A simple shift in focus can lead to significant improvements in efficiency and safety.

When selecting a stainless valve stem, it’s essential to understand the types available. Generally, stainless valve stems can be categorized into two types:

solid and

hollow.

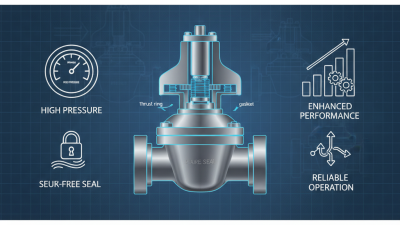

Solid valve stems are often used in applications requiring durability. These are typically heavier and can withstand extreme pressure.

Hollow valve stems, on the other hand, are lighter. They provide better thermal expansion properties. Industry studies suggest that up to 30% of high-performance applications prefer hollow versions. This is due to their ability to handle various pressure conditions effectively.

Tip: Evaluate the operating environment. High-temperature situations may favor solid stems. Conversely, lighter stems might be preferable for areas with lower loads.

Another consideration is the finish of the valve stem. Common finishes include polished and passivated. Polished stems have a shiny surface, providing aesthetic appeal and better resistance to corrosion. Passivated stems undergo a chemical treatment that enhances protection against rust. Specifications indicate that passivated stems can last up to 50% longer in corrosive environments.

Tip: Inspect valve stems closely. Look for any signs of wear or flaws before deciding. Each type has its strengths and weaknesses. It’s crucial to find a balance that suits your specific needs.

When choosing a stainless valve stem, material properties are key. The selection often lies between 304 and 316 stainless steel. They are both popular, but their differences can impact performance.

304 stainless steel is more common, known for its good corrosion resistance. It's suitable for many applications but may not hold up in harsh environments. In contrast, 316 stainless steel contains molybdenum, enhancing its resistance to pitting and chloride corrosion. According to industry reports, 316 can be crucial for marine applications.

Tips: Always assess the working environment. If the valve needs to withstand extreme conditions, opt for 316.

Other alloys exist, too. For example, super duplex steels can offer better performance in specific situations. However, they are often more expensive and may not be readily available. Not all projects require high-end alloys, so evaluating project needs is crucial.

Tips: Consider both cost and longevity. Sometimes, a simpler alloy is adequate. Balancing budget and application can make your choice more pragmatic.

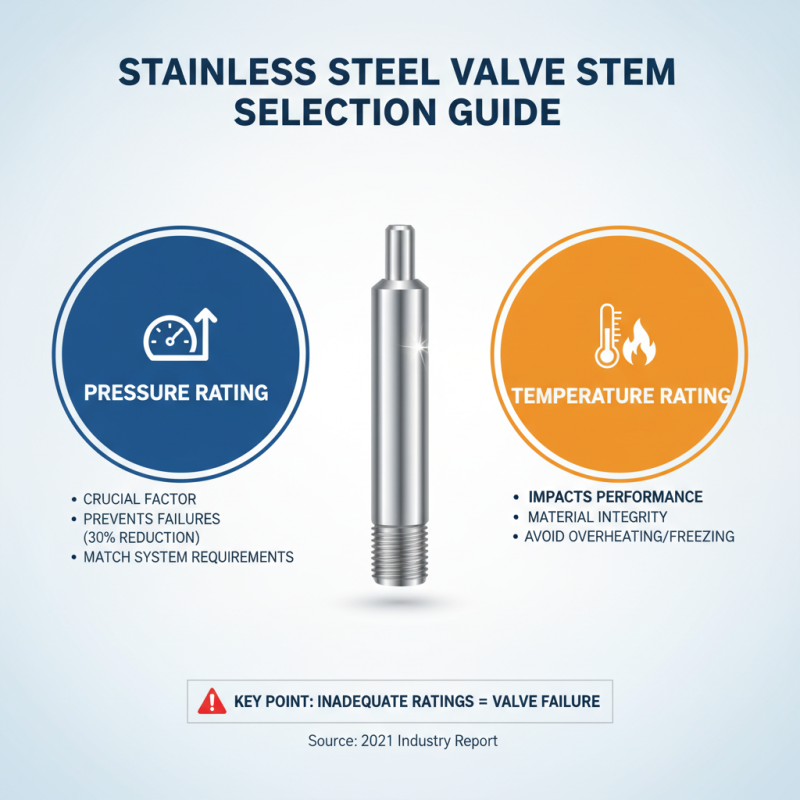

When selecting a stainless valve stem, it's crucial to consider pressure and temperature ratings. These factors significantly impact performance. Research shows that valve failures often stem from inadequate pressure handling. A 2021 report indicates that up to 30% of valve malfunctions relate to pressure oversights.

Temperature ratings play a similar role. The material can lose integrity at high temperatures. According to industry standards, stainless steel valves can have temperature limits ranging from -196°C to 1,200°C. Ensuring your valve operates within these limits is vital. Many users overlook this aspect, leading to premature wear and system inefficiencies.

It's important to evaluate the specific conditions of your application. Not all stainless steel is created equal. Variants like 304 and 316 have different performance ratings. Make sure you don’t choose a valve that fails under pressure or temperature extremes. Miscalculating these factors can result in costly repairs down the line.

Choosing the right stainless valve stem is crucial for various applications. It’s essential to consider the fluid types it will handle. Different fluids can have different corrosive properties. A valve stem that resists corrosion can greatly enhance longevity. For example, stainless steel 316 is often preferred for its excellent corrosion resistance against harsh environments.

Tips: Always check the chemical compatibility of the valve stem with the fluid. A mismatch can lead to unexpected failures. It's wise to consult compatibility charts before making a selection.

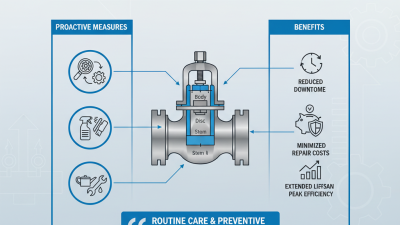

Some fluids can contain impurities that might affect valve performance. This often gets overlooked during the selection process. Ensure that the chosen material is rated for the specific conditions expected in your system. Regular monitoring and maintenance are also vital. A small oversight can lead to significant issues later on.

Tips: Regularly inspect valves for signs of wear and corrosion. Maintenance can prolong service life and prevent costly repairs. Do not wait for a failure to occur before addressing potential problems. Choosing the correct stainless valve stem from the beginning is less costly than replacing damaged components later.

| Fluid Type | Stainless Steel Grade | Corrosion Resistance | Operating Temperature (°C) | Recommended Application |

|---|---|---|---|---|

| Water | 304 | Good | -20 to 80 | General Plumbing |

| Acidic Fluids | 316 | Excellent | -20 to 100 | Chemical Processing |

| Oil and Gas | Duplex (2205) | Very Good | -50 to 65 | Oil Exploration |

| Steam | 316L | Good | -20 to 150 | Steam Systems |

| Food Products | 316 | Excellent | 0 to 100 | Food Processing |

When selecting a stainless valve stem, cost-effectiveness is crucial. Quality and budget must align. According to industry reports, the price of stainless steel components can vary widely. Some high-end options may exceed $500, while budget solutions can be found for under $100. Balancing these factors can be challenging.

Consider the material's durability. High-quality stainless steel offers resistance to corrosion and wear. It prolongs lifespan and minimizes replacement costs. However, cheaper alternatives might save money initially but could lead to higher expenses long-term. A report from a leading manufacturing association indicates that poor-quality components can result in operational failures, costing companies thousands in repairs.

It’s important to evaluate your specific needs. Will the valve stem undergo extreme conditions? If yes, investing in superior quality is wise. If it's for a less demanding application, a budget option might suffice. Sometimes, less expensive choices seem appealing but could compromise reliability. Decisions should reflect not only immediate costs but also future implications.

This chart illustrates the average costs of different types of stainless valve stems, including Standard, Premium, Industrial, and Custom options. Understanding these costs can help in balancing quality and budget in your selection process.