When embarking on a project that requires precision and reliability, selecting the right CNC machined valve body can make all the difference. As industry expert John Reynolds, a leading engineer in the CNC machining sector, wisely states, “The heart of any hydraulic or pneumatic system lies in its valve body; it must be designed and machined with utmost accuracy to ensure optimal performance.” This highlights the critical nature of choosing the appropriate CNC machined valve body to meet the specific demands of your project.

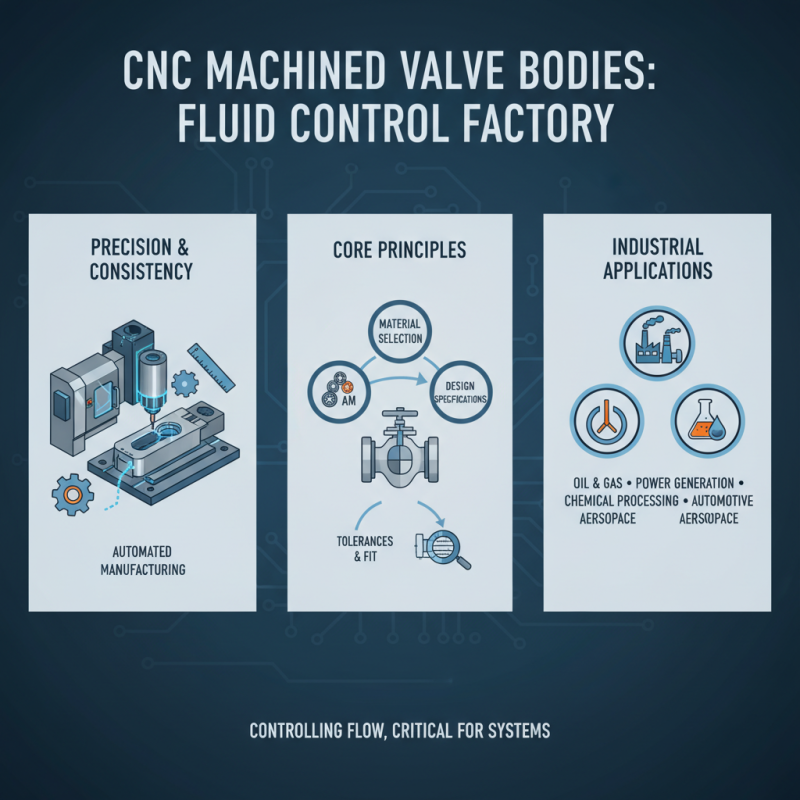

In today's fast-paced manufacturing landscape, understanding the intricacies involved in the selection process is paramount. Factors such as material selection, machining accuracy, and design specifications play crucial roles in the performance and longevity of the valve body. By focusing on these elements, engineers and project managers can not only enhance the functionality of their systems but also streamline production processes, ultimately leading to cost savings and improved operational efficiency.

As we explore the considerations for choosing the right CNC machined valve body, it is essential to keep in mind the specific needs of your project and the environment in which the component will operate. With the right knowledge and guidance, you can ensure that your choice will support the success of your system and deliver the level of precision that today’s applications demand.

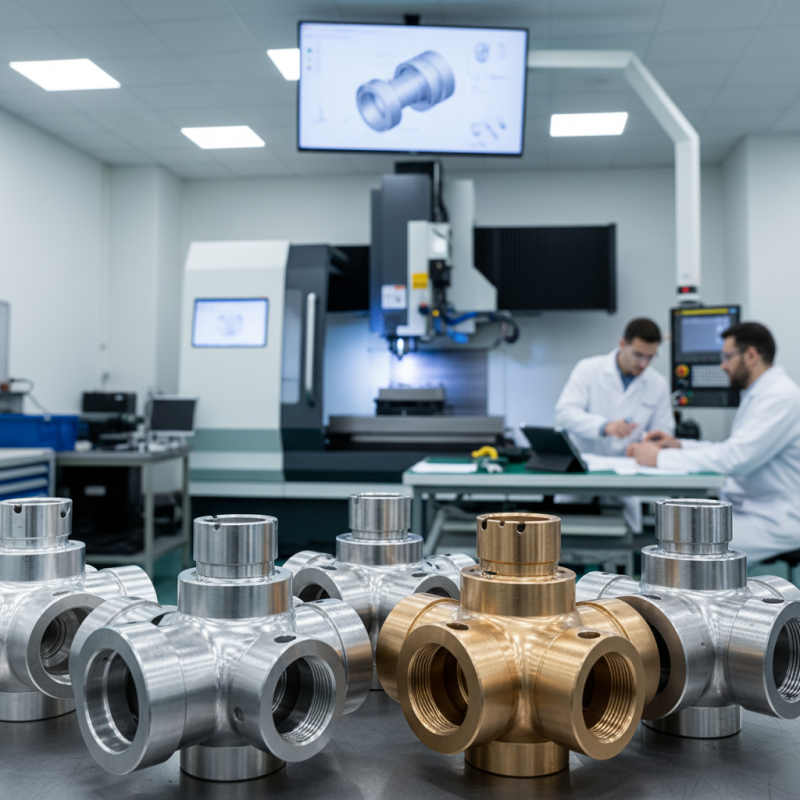

CNC machined valve bodies play a critical role in various industrial applications, acting as the core components that control fluid flow in systems. Understanding the basics of these valve bodies is essential for selecting the right one for your project. A CNC (Computer Numerical Control) machined valve body is crafted using automated machinery that ensures precision and consistency in each part. The material selection, design specifications, and tolerances of the valve body must align with the operating requirements of the application it serves.

When choosing a CNC machined valve body, consider the specifications of your system. The pressure rating, fluid type, and temperature range are vital factors that influence the design and material of the valve body. Additionally, the machining process ensures that each component meets high standards of performance and reliability.

Tips: Always verify the compatibility of the valve body material with the fluids handled in your system to prevent corrosion and wear. Furthermore, focus on the tolerances required for your application; improper tolerances can lead to inefficiencies and potential system failures. Engaging with a knowledgeable supplier can provide insights and recommendations that align with your project's specific demands.

When it comes to selecting the right CNC machined valve body for your project, the first step is to clearly identify your project requirements. This involves understanding the specific application for which the valve body will be used, including factors such as pressure and temperature conditions, fluid types, and flow rates. By assessing these parameters, you can begin to narrow down your options and ensure that the valve body you choose will meet the demands of your system.

Another important consideration is the material compatibility of the valve body. Depending on the environment in which the valve will operate, certain materials may be more suitable than others. For instance, if the valve body needs to resist corrosion or wear, it may be necessary to select materials that offer enhanced durability. Additionally, the size and connection type of the valve body should be evaluated to guarantee proper integration with existing systems.

By taking the time to thoroughly define your project requirements, you will be better positioned to make an informed decision that enhances efficiency and performance in your application.

When selecting the right material for CNC machined valve bodies, it’s essential to consider the application and environmental conditions the valve will face. Common materials include aluminum, stainless steel, and plastic, each offering a unique set of advantages. Aluminum is lightweight and offers good corrosion resistance, making it ideal for applications where weight savings are crucial. Stainless steel, on the other hand, provides superior strength and durability, especially in high-pressure situations. For less demanding environments, plastic can be a cost-effective option, though it may lack the strength needed for more rigorous applications.

Tips for choosing the right material include evaluating the operational temperature range and pressure thresholds. Always assess the chemical compatibility of the material with the fluids being controlled to avoid premature failure. It’s also beneficial to consider manufacturing tolerances required for your specific application, as this can influence the choice of material due to machining characteristics.

Another key factor is the finish required for the valve body. Certain materials can be easier to machine with precise finishes, while others may require additional processing steps to meet specifications. Understanding the finishing processes required for each material will aid in making a more informed choice, ensuring both performance and longevity in your CNC machined valve body.

When selecting a CNC machined valve body for your project, understanding precision and tolerance requirements is crucial. Precision in machining refers to the degree to which the finished product matches the specified dimensions. According to a report from the American Society of Mechanical Engineers, achieving tolerances within ±0.001 inches is considered high precision for many valve applications, particularly in industries such as aerospace and automotive where performance and safety are paramount. Tolerance levels dictate the allowable variation in dimensions and can significantly impact the functionality and reliability of the valve body.

Different applications demand varying tolerance levels, based on factors such as fluid dynamics, pressure levels, and the intended environment. For instance, valve bodies designed for high-pressure systems may require tighter tolerances to prevent leaks and ensure operational efficiency. The International Organization for Standardization (ISO) notes that tighter tolerances can lead to higher manufacturing costs, thus it’s essential to balance the required precision with budget constraints. Utilizing advanced CNC machining technologies can help achieve the desired precision, with reports indicating that implementing these technologies can improve production efficiency by up to 30%. Therefore, assessing both precision requirements and acceptable tolerances is vital for successful project outcomes.

| Project Type | Material | Precision Level (mm) | Tolerance Range (mm) | Application |

|---|---|---|---|---|

| Hydraulic Systems | Aluminum Alloy | 0.01 | ±0.02 | Industrial Machinery |

| Water Supply | Stainless Steel | 0.02 | ±0.05 | Plumbing |

| Automotive Parts | Carbon Steel | 0.01 | ±0.03 | Vehicle Engineering |

| Aerospace Components | Titanium Alloy | 0.005 | ±0.01 | Aerospace Engineering |

| Oil & Gas | Nickel Alloy | 0.01 | ±0.02 | Energy Sector |

When it comes to choosing a reliable manufacturer for your CNC machined valve body needs, several key factors should be considered to ensure quality and performance. First, evaluating the manufacturer’s reputation is crucial. Look for companies with a strong track record in the industry, characterized by positive customer testimonials and high-quality standards. An established manufacturer is likely to have refined their production processes over time, leading to superior craftsmanship and attention to detail.

Additionally, assess the manufacturer’s ability to meet specific project requirements. This includes their capacity to handle custom designs, the materials they use, and their precision in machining techniques. A reliable manufacturer should be able to provide certifications and quality assurance documentation, as well as communicate effectively about their production capabilities. Engaging in dialogue about their processes and previous work can provide insights into whether they can deliver the valve bodies that meet your project's demands. Ultimately, selecting a manufacturer that aligns with your quality expectations and technical requirements will greatly contribute to the success of your project.