In today's industrial landscape, the efficiency and reliability of fluid transfer systems are paramount. Among the critical components that facilitate these processes is the Camlock Valve, known for its ease of use and versatility in various applications. According to a recent market analysis report by Research and Markets, the global valve market is anticipated to reach $90 billion by 2025, with a significant portion attributed to the increased demand for efficient piping systems across sectors like oil and gas, water treatment, and chemical processing.

Choosing the right Camlock Valve is essential for optimizing the performance of your piping system. Factors such as material selection, temperature tolerance, and pressure ratings play crucial roles in the valve’s suitability for specific applications. Moreover, it's vital to consider compatibility with the fluids being transported, as improper selection can lead to failures that compromise system integrity and safety. With the projected growth in industrial activities, understanding these factors will ensure that valves not only meet regulatory standards but also improve operational efficiency, ultimately contributing to enhanced productivity and reduced maintenance costs.

Camlock valves play a crucial role in the functioning of various piping systems, allowing for quick and efficient connections between hoses and pipes. These valves operate on a simple mechanism that enables the user to connect or disconnect the piping effortlessly. The camlock design features a series of levers that lock the coupling in place once it is securely attached. This not only ensures a tight seal but also allows for easy operation, making camlock valves an ideal choice for applications that require frequent changes in flow direction or connections.

In addition to ease of use, camlock valves offer versatility in terms of materials and sizes, catering to a wide range of industrial applications. They can handle different media, including water, chemicals, and petroleum products, making them suitable for diverse environments. Understanding the specific functionality of camlock valves can aid in selecting the right type for your piping system. Factors such as pressure ratings, flow requirements, and the nature of the substances being transported should all be considered. By evaluating these criteria, you can ensure that the camlock valve you choose will not only fit seamlessly within your system but also enhance operational efficiency.

| Valve Type | Material | Size (Inches) | Pressure Rating (PSI) | Temperature Range (°F) | Applications |

|---|---|---|---|---|---|

| Standard Camlock | Aluminum | 1.5 | 150 | -40 to 150 | Water, Chemicals |

| Dust Cap | Polypropylene | 2 | 50 | 0 to 120 | Dust Protection |

| Camlock Adaptor | Stainless Steel | 3 | 300 | -20 to 200 | High-Pressure Applications |

| Quick Coupler | Brass | 1 | 75 | -10 to 180 | Oil, Fuel |

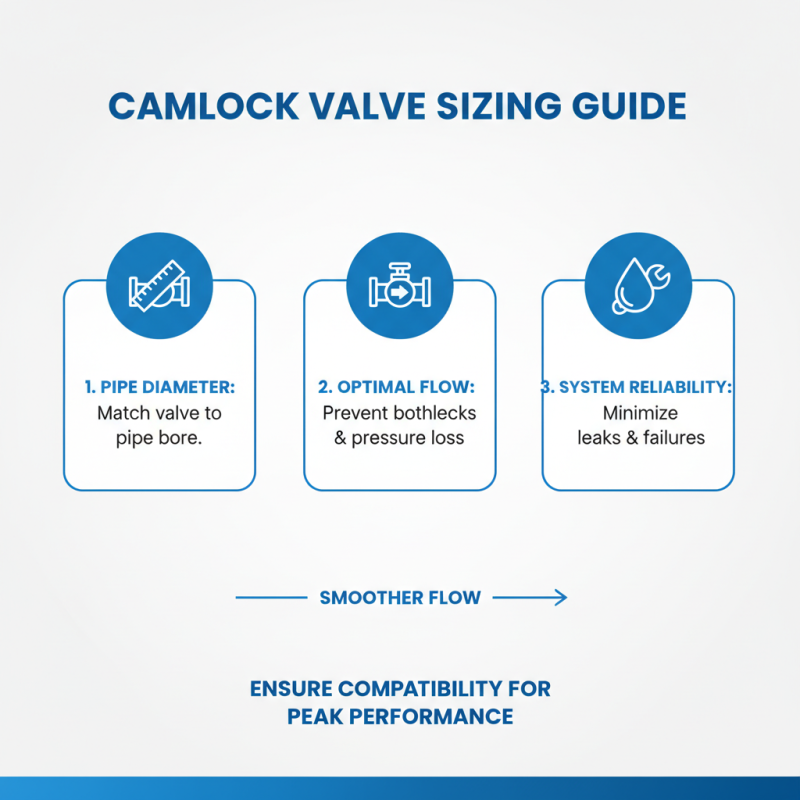

When selecting a camlock valve size for your piping system, it is essential to consider various factors to ensure optimal performance and functionality. One of the primary considerations is the diameter of the piping system. The size of the camlock valve should match the nominal bore of the pipes to prevent bottlenecks or excessive pressure loss. An adequately sized valve allows for smoother flow and minimizes the risk of leaks or failures within the system.

Another factor to contemplate is the specific application and type of media being transported. Different applications may require different flow rates, and the camlock valve should facilitate these requirements efficiently. Additionally, the chemical compatibility of the valve material with the transported media is crucial to avoid corrosion or degradation over time.

Tip: Always consult engineering specifications to determine the appropriate pressure ratings and sizes, as this will guide you in selecting a valve that can handle the operational conditions of your system.

Consider also the installation space and accessibility for maintenance. A larger valve might be more efficient but could also require more space and could pose challenges for future repairs. Balancing size with serviceability ensures that your system remains efficient while being manageable over its lifespan.

Tip: Keep future upgrades in mind when selecting a valve size. Choosing a slightly larger valve than currently needed can provide flexibility for increased flow rates or expanded applications down the line.

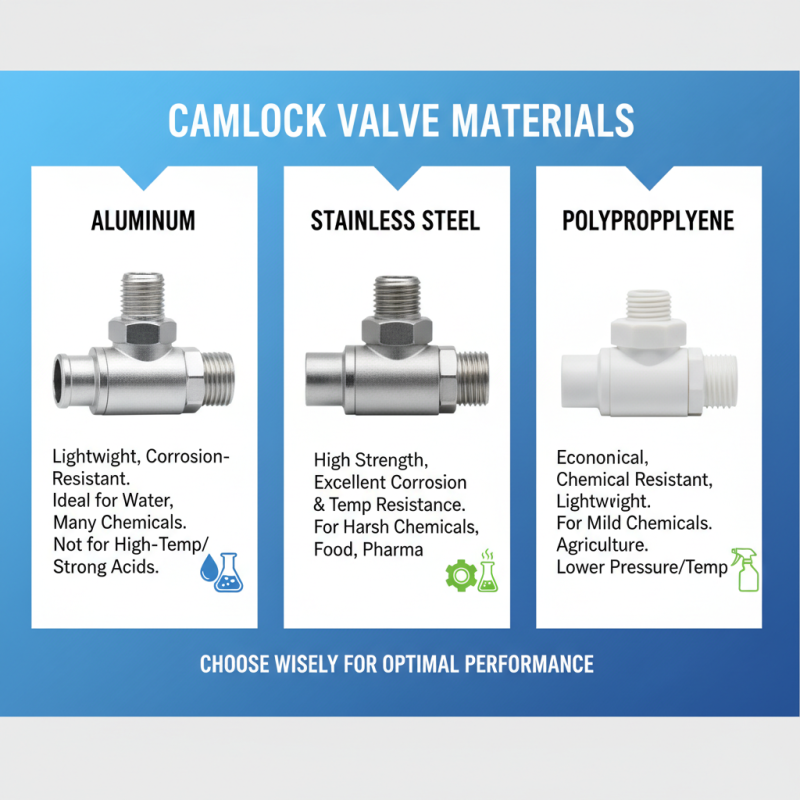

When selecting a camlock valve for your piping system, understanding the material options available is crucial for ensuring optimal performance and longevity. Camlock valves are commonly made from materials such as aluminum, stainless steel, and polypropylene, each offering distinct advantages depending on the intended application. Aluminum camlock valves are lightweight and resistant to corrosion, making them ideal for non-potable water and various chemical applications. However, they may not be suitable for high-temperature or highly corrosive environments.

On the other hand, stainless steel camlock valves are known for their exceptional durability and resistance to extreme temperatures and corrosive substances. This makes them a popular choice for food processing, pharmaceuticals, and other industries where hygiene and material integrity are paramount. For applications involving less volatile substances, polypropylene camlock valves provide a cost-effective alternative, featuring excellent resistance to many chemicals, though they should be avoided in applications involving high temperatures or high-pressure situations.

By carefully considering the specific needs of your piping system and the properties of each material, you can make an informed decision that ensures the reliability and efficiency of your valve system.

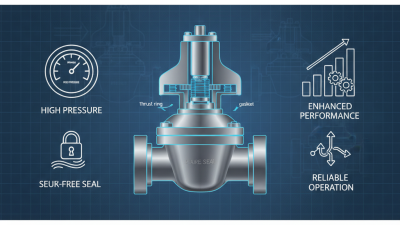

When selecting a camlock valve for your piping system, understanding pressure ratings and flow characteristics is essential. Pressure ratings indicate the maximum pressure the valve can handle safely, which is crucial for maintaining system integrity and efficiency. It is important to match the valve's rating with the needs of your system to prevent leaks or failures. When evaluating these ratings, consider the fluid type, temperature, and the application environment to ensure that the camlock valve performs optimally.

Flow characteristics play a vital role in determining how well a camlock valve will function in your system. The valve's design affects the flow rate and can impact the overall efficiency of your piping setup. An ideal valve should not only accommodate the necessary flow rates but also minimize pressure drops across the system. Evaluating the diameter and geometry of the valve can help in ensuring that your system keeps up with the required performance levels.

Tips: When assessing camlock valves, always refer to technical specifications provided by manufacturers. Additionally, consulting with industry experts can provide insights into the best practices related to specific applications. Always perform a compatibility check between the valve materials and the fluids being transported to enhance longevity and performance.

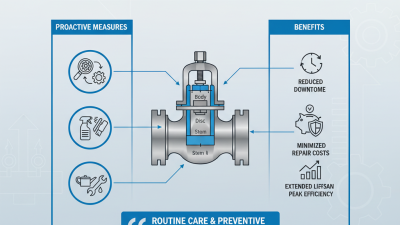

When considering the installation and maintenance of camlock valves, understanding proper practices is essential for ensuring reliability and longevity in piping systems. These valves, widely used across various industries, require careful handling. According to the Fluid Control Institute, effective maintenance can reduce the likelihood of system failures by up to 30%, thus stressing the importance of routine inspections and upkeep. Operators should inspect seals regularly, as deteriorated seals can lead to leaks and inefficiencies in fluid handling.

Additionally, ensuring that camlock valves are installed using proper torque specifications is critical. The American Society of Mechanical Engineers (ASME) recommends adhering to the manufacturer’s guidelines while securing fittings, as improper assembly can lead to mechanical failures. To promote optimal performance, it is beneficial to incorporate periodic cleaning protocols to prevent debris accumulation within the valve. According to industry benchmarks, a well-maintained camlock valve can outlast its poorly maintained counterpart by a factor of three, underscoring the importance of proper installation practices. Taking these steps can significantly enhance the performance of your piping system and prevent unnecessary downtime.