In the industrial sector, the choice of valve type is crucial for operational efficiency. Bolted Bonnet valves stand out for their reliable sealing and durability. According to a recent report by Grand View Research, the global valve market is projected to reach $100 billion by 2025, with Bolted Bonnet valves playing a significant role in this growth.

These valves are favored in various applications, such as oil and gas, and water treatment. Their construction allows for easy maintenance. A 2022 study conducted by MarketsandMarkets highlighted that 45% of industries favor Bolted Bonnet designs over other types. However, understanding the specific installation environments remains essential.

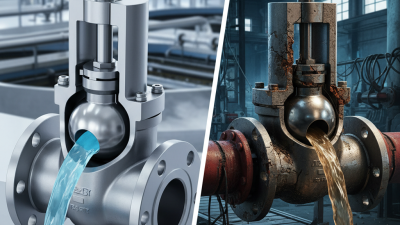

It's worth noting that while Bolted Bonnet valves are effective, their performance can vary based on material and pressure conditions. In some cases, they may underperform if improperly installed or maintained. This complexity calls for careful evaluation in every industrial setting.

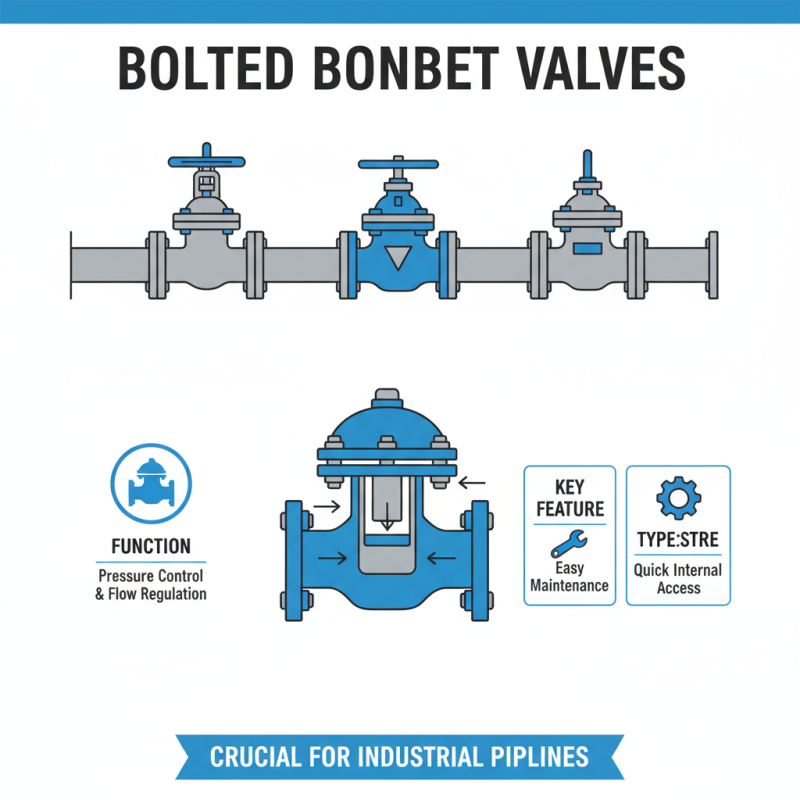

Bolted bonnet valves are widely used in various industrial applications. They are crucial for maintaining pressure and controlling flow in pipelines. These valves come in different types, each with unique features. For example, standard bolted bonnet valves are easy to maintain. Their design allows for quick access to internal components.

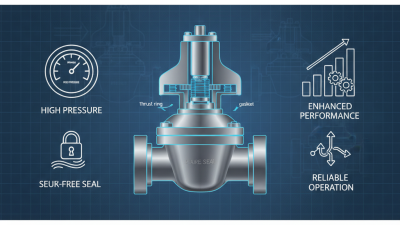

There are also globe bolted bonnet valves. They provide excellent throttling capabilities. According to industry data, they can perform effectively in high-pressure situations. Typically, they have a longer lifespan due to their sturdy construction. However, their flow coefficient (Cv) may be lower compared to other valve types.

Another common type is the gate bolted bonnet valve. It offers minimal flow resistance. This can be advantageous in applications requiring full flow. However, these valves are not ideal for throttling. Users often overlook this aspect. Misjudging the valve type can lead to inefficiencies in the system. Choosing the right bolted bonnet valve is, therefore, vital for operational success.

Bolted bonnet valves are crucial in various industrial fields. Their design ensures a tight seal under pressure, making them reliable. These valves are widely used in oil and gas, water treatment, and chemical processing. In these sectors, they handle high pressures and temperatures well. Bolted bonnet valves provide ease of maintenance, allowing for quick disassembly.

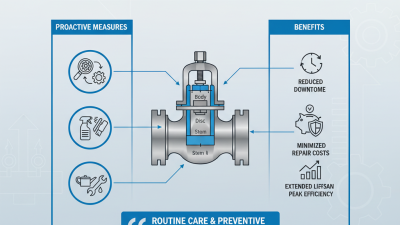

Tips: Regular maintenance is vital. Inspect your bolted bonnet valves frequently. A small leak can lead to big problems.

In water treatment facilities, bolted bonnet valves control flow effectively. They help manage pressure surges. In chemical processing, they prevent leaks of hazardous materials. Yet, improper installation can lead to failures. Always ensure alignment during installation.

Tips: Consider using a torque wrench. It ensures bolts are tightened correctly. This step can prevent future leaks.

In the oil and gas industry, they are favored for upstream and downstream applications. However, they can become a risk if not monitored. Corrosion may go unnoticed without regular checks, leading to potential failures. Prioritize routine inspections to maintain safety and efficiency.

This chart illustrates the common applications of bolted bonnet valves across various industries, highlighting their widespread use in water treatment, oil and gas, chemical processing, and power generation sectors.

Bolted bonnet valves are known for their sturdy design and versatility. These valves are used in a range of industrial applications, such as oil, gas, and water systems. One significant advantage is their ability to maintain a strong seal. They can handle high pressure and temperature conditions. This makes them reliable in demanding situations.

Another benefit of using bolted bonnet valves is ease of maintenance. Their design allows for simple disassembly without removing the valve from the pipeline. This feature saves time and labor costs. However, the bolts may require regular inspection to ensure tightness. Loose bolts can lead to leaks and safety issues.

Bolted bonnet valves also provide flexibility in operation. They can be easily installed in various orientations. This characteristic offers options for space-constrained areas. On the downside, these valves can sometimes be heavier than other types. This could be a concern in lightweight installations. Users must consider these factors before choosing.

| Valve Type | Material | Pressure Rating (psi) | Temperature Range (°F) | Applications | Advantages |

|---|---|---|---|---|---|

| Standard Bolted Bonnet | Carbon Steel | 150 - 300 | -20 to 250 | Water, Oil, Gas | Ease of maintenance, Durable, Versatile |

| High Temperature Bolted Bonnet | Stainless Steel | 600 - 1500 | -40 to 800 | Steam, Chemical Processing | High strength, Corrosion resistant |

| Cryogenic Bolted Bonnet | LNG Steel | 150 - 600 | -320 to 32 | Liquefied Natural Gas | Designed for low temp, Safe operation |

| API 6D Bolted Bonnet | Alloy Steel | 150 - 2500 | -20 to 350 | Oil & Gas Transmission | Industry standards, High reliability |

Bolted bonnet valves are essential in many industrial processes. Regular maintenance and inspection are crucial to ensure their proper function. These valves are often subjected to extreme conditions, leading to wear and tear. Performing regular checks can help identify issues early on.

Inspecting the bolts and the bonnet is vital. Loose bolts can lead to leaks, which may escalate into serious problems. A simple visual inspection can reveal rust or corrosion. This often indicates that maintenance is overdue. Tightening bolts should be part of a routine checklist.

Another area to focus on is the sealing surfaces. Over time, they can become damaged. This situation can compromise the valve’s integrity. Using a specialized tool for measuring flatness may be beneficial. However, not everyone considers this step important. Ignoring such details can cause significant failures later. Adequate documentation of inspections is often overlooked as well. This practice could help track issues over time, making maintenance more effective.

When selecting a bolted bonnet valve, several key considerations come into play. The design and material of the valve significantly affect its performance and longevity. For instance, carbon steel valves offer good strength in moderate temperatures, while stainless steel excels in corrosive environments. According to industry reports, nearly 40% of valve failures are linked to improper material selection.

Pressure rating is another vital factor. Valves must match the specific application requirements. For high-pressure systems, choosing a valve that can withstand extreme conditions is essential. Failure to do so could result in costly downtime or accidents. It's important to check compliance with relevant standards.

**Tips:** Always consult pressure-temperature charts. They help in identifying suitable materials. Regular maintenance checks can also extend a valve's operational life. The right choice today can prevent leaks and reduce expenses in the long run. Analyze your specific application needs before making a decision. Each valve operates differently based on its design. Not all seem ideal for every situation.