The Ball Valve Body plays a crucial role in fluid control across various industries. According to a report by Transparency Market Research, the global ball valve market is projected to reach $14 billion by 2026, highlighting the growing significance of this component. Properly functioning ball valve bodies ensure smooth operation, minimize leakage, and enhance safety in processes, from oil and gas to water treatment.

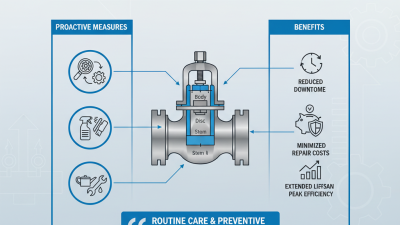

Recent studies reveal that over 30% of valve failures are due to the deterioration of the ball valve body. This can lead to downtime and increased operational costs. Visualizing this, a faulty ball valve can disrupt an entire production line, emphasizing its importance. Yet, many still overlook regular maintenance, wasting resources and risking safety.

Understanding the design and materials of the ball valve body is vital. A strong, corrosion-resistant body can greatly enhance its lifespan. However, not all manufacturers meet these quality standards. This inconsistency leads engineers to reflect on the reliability of their choices. In the increasingly competitive market, ensuring the integrity of the ball valve body is essential for optimal fluid control and overall system performance.

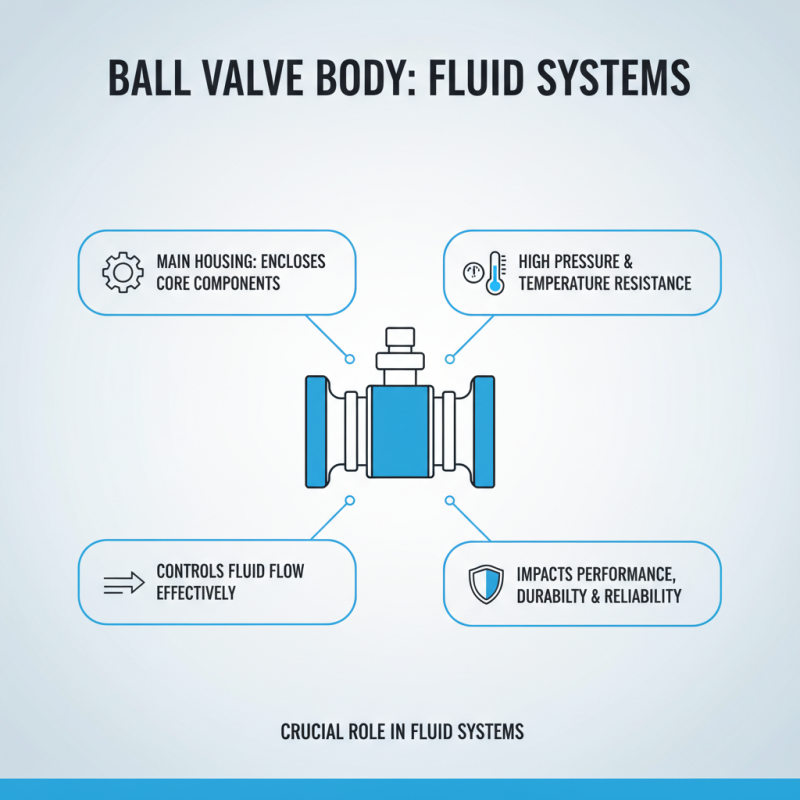

The ball valve body plays a crucial role in fluid systems. It serves as the main housing that encloses the valve's core components. This body is typically designed to withstand high pressure and temperature. It directly influences the valve’s performance, durability, and reliability. A sturdy body can effectively control fluid flow.

Tips: Regular maintenance of the valve body is essential. Inspect for cracks or corrosion frequently.

Another aspect to consider is the material of the ball valve body. Different materials offer various benefits. Always choose a material that suits your specific application. A mismatch can lead to inefficiencies or failures.

Tips: Consult a professional if you’re unsure about the right material. Investing time in research can save costs later.

The body of a ball valve is crucial for effective fluid control. It defines the pathway through which fluids flow. The materials used, such as stainless steel or PVC, significantly affect durability and performance. A well-designed body can withstand high pressures and corrosion. This ensures reliability in various applications, from industrial processes to home plumbing.

A ball valve body is typically spherical, allowing for smooth fluid passage. This design minimizes turbulence, reducing the chance of wear. The port design is another essential feature. Full-port valves allow unrestricted flow, while reduced-port options save space. Each design has specific uses that must be understood for optimal performance.

However, there are challenges. An improperly designed body can lead to leaks and inefficiency. Users may overlook maintenance, risking failure. Understanding these design features is essential. They dictate the valve's lifespan and suitability for different applications. When considering a ball valve, the body’s design cannot be ignored.

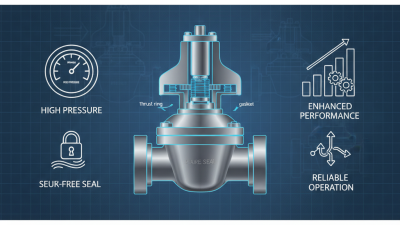

The ball valve body plays a pivotal role in fluid control systems. It serves as the central component that regulates the flow of liquids and gases. The design of the valve body significantly impacts the efficiency of fluid flow. A well-crafted body reduces turbulence and ensures a smooth passage for media. This smooth flow helps maintain optimal pressure conditions.

When examining how ball valve bodies influence fluid flow, it’s clear that size and material matter. A larger flow area allows more fluid to pass through, while the right material can prevent corrosion and wear. However, choosing the right combination can be tricky. Not every material suits all fluids. For instance, some materials degrade quickly when exposed to certain chemicals.

Pressure control is also intertwined with the valve body. A tight seal minimizes leaks and maintains system pressure. Users often overlook this aspect, leading to inefficiencies. An improperly designed valve body can result in excessive wear and tear. Reflecting on these factors is essential for achieving optimal performance in fluid systems. Consider the unique needs of your applications before making a decision.

The ball valve body is critical for effective fluid control. Different materials play a significant role in its construction. Stainless steel is a popular choice. It offers strength and resistance to corrosion. However, it can be expensive. Considerations must be made based on the application.

Another common material is brass. Brass valves are less costly and durable. They work well in various environments. Yet, they may not hold up in extreme conditions. This raises concerns for long-term applications.

Plastic options are lightweight and resistant to chemical corrosion. They are ideal for certain fluids. However, they may not withstand high pressure. Each material comes with its pros and cons. Decision-makers must reflect on their needs carefully. Choosing the right material affects performance and longevity.

Ball valve bodies are vital components in many industries, offering reliable fluid control. In oil and gas, they regulate the flow of crude oil and natural gas. Their ability to provide a tight seal makes them perfect for high-pressure applications. Moreover, industries like water treatment rely on ball valves to manage the flow of water with precision.

In food and beverage production, ball valve bodies ensure safety and cleanliness. They handle various liquids, like syrups and juices, without contamination. The smooth operation is crucial during production cycles. A minor flaw can lead to product wastage. This aspect demands diligence from operators.

In chemical processing, durability is essential. The materials used in ball valve bodies must withstand corrosive substances. A failure in this context can have severe consequences. Maintenance is not always prioritized, leading to potential risks. Controlling fluid flow in a reliable way should not be taken lightly.