In the world of automotive performance, the "Forged Valve Body" stands out as a revolutionary component. Expert engineer Tom Reynolds states, "The right forged valve body can dramatically enhance vehicle responsiveness." This emphasizes the critical role of quality in valve body construction.

The 2026 market offers numerous options for forged valve bodies. Each option promises improvements in performance, making the decision challenging. Not all products deliver on their promises, though. Some may lack the durability or precision desired. As consumers, we must avoid simply choosing based on brand reputation.

The effectiveness of a forged valve body often boils down to its design and materials. Despite advancements, manufacturers still grapple with consistency issues. The challenge lies in balancing performance and quality. It's essential to assess both the benefits and potential drawbacks before making a purchase. Each selection has its unique features, making thorough research crucial for optimized results.

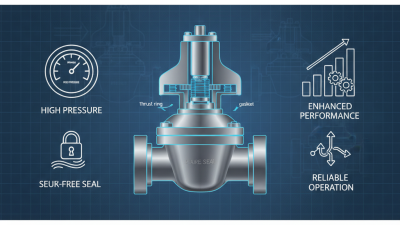

Forged valve bodies play a crucial role in enhancing automotive performance. They provide superior strength and durability compared to cast alternatives. This difference is significant; data from the Automotive Engineering Institute shows that forged components can withstand pressures 50% higher than their cast counterparts. This resilience is essential for high-performance engines that demand reliability under extreme conditions.

Engineers appreciate the precision of forged valve bodies. Their manufacturing process allows for tighter tolerances and improved weight distribution. This can lead to better throttle response and increased power output. According to a recent report by the International Journal of Automotive Technology, optimized valve body designs can improve fuel efficiency by up to 7%. However, achieving these benefits requires careful design and engineering expertise.

Challenges exist in the production of forged valve bodies. While they offer enhanced performance, the cost can be prohibitive for some applications. Additionally, the machining process can introduce variability in quality. Manufacturers must balance performance with budget constraints. These factors lead to a need for continuous improvement and reflection in the production processes. Advanced scanning technologies and simulations may help address these issues, ensuring that forged valve bodies meet the high standards required by performance enthusiasts.

When selecting the best forged valve body, key features play a crucial role in performance. A well-engineered valve body enhances not just functionality but longevity. Look for precision machining. This ensures smooth operation and minimizes wear. Materials also matter significantly; high-quality steel or aluminum can improve durability.

Another vital aspect is weight reduction. A lightweight valve body can enhance responsiveness without sacrificing strength. Check the design for optimal fluid flow. This can lead to better performance and efficiency in various applications. Some products might compromise flow for cost savings, so remain vigilant.

Finally, consider the level of customization available. Some forged valve bodies offer adjustable features, which can cater to specific needs. It’s essential to prioritize your requirements over brand reputation. Engaging with experts for insights can reveal details not easily accessible. Reflect on your needs, and don't settle for less.

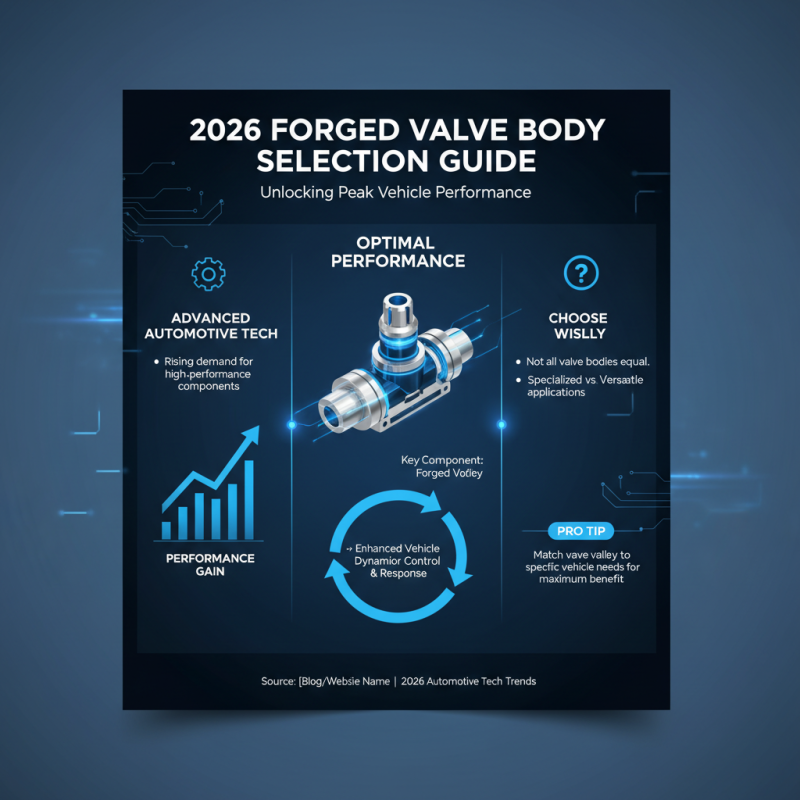

As automotive technology advances, the demand for high-performance components rises. In 2026, selecting the right forged valve body could significantly enhance vehicle performance. Not all valve bodies perform the same. Some models excel in specific applications but might lack versatility.

Current industry reports highlight that forged valve bodies can improve durability and efficiency. Models incorporating advanced materials show a 20% increase in strength compared to traditional options. This is crucial in high-stress environments. However, some users report issues with compatibility, leading to inefficiencies in certain builds. A careful selection based on vehicle specifications is essential.

Moreover, testing reveals that specific brands have lower heat resistance, affecting performance at high temperatures. On the other hand, options with upgraded designs can offer better thermal stability. It's important to weigh these factors when choosing. Enthusiasts should consider the unique needs of their engines and be cautious of overestimating the benefits of certain models. Making informed decisions will lead to improved performance and longevity on the road.

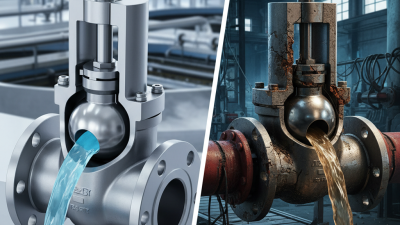

When analyzing forged valve bodies versus traditional options, several key factors emerge. Forged valve bodies boast higher strength and durability. They can withstand extreme pressures and resist deformation better than their traditional counterparts. This is crucial for high-performance applications where reliability is essential.

However, the manufacturing process can be complex and costly. Not every manufacturer provides this technology, which may lead to limited availability. Traditional valve bodies, while generally more affordable, might not offer the same performance gains. They can be sufficient for everyday use, but performance enthusiasts often seek something more robust.

Consumers should weigh these factors carefully. Are the gains in performance worth the price increase? Not every setup will benefit equally from upgraded components. It's also important to consider compatibility with existing systems. This decision demands thoughtful reflection on personal needs and driving styles.

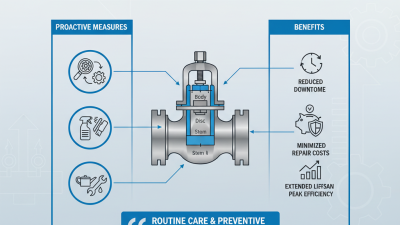

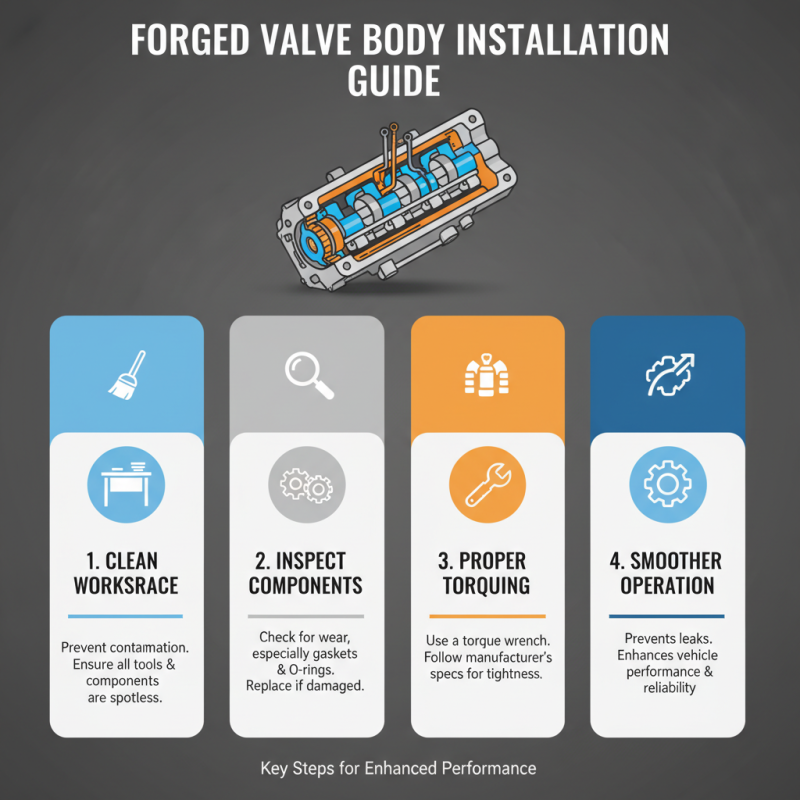

When it comes to enhancing vehicle performance, forged valve bodies play a crucial role. Proper installation is key. Start with a clean workspace to avoid contamination. Check all components for wear. Inspect gaskets and O-rings closely. Use a torque wrench to ensure proper tightening. This prevents leaks and can lead to smoother operation.

Maintenance should not be overlooked. Regular fluid checks extend the life of valve bodies. Industry data suggests that 70% of performance issues arise from dirty or low fluid levels. It's important to replace fluids according to manufacturer recommendations. Skipping this step can lead to premature wear and costly repairs.

Consider periodic inspections of the valve body. Look for signs of wear or damage. Interestingly, some studies indicate that over 40% of valve body failures are due to neglected maintenance. Small issues, if not addressed, can escalate quickly. Proper care can significantly enhance vehicle performance and longevity.