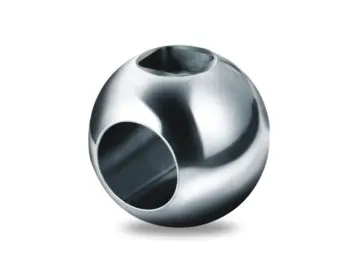

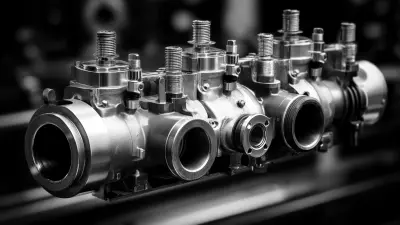

Top Bottom Entry Ball Valves: Reliable Options for Any Application

The Best Bottom Entry Ball Valve offers exceptional reliability for fluid control systems, characterized by its superior quality and performance. With the ability to manage high pressure and flow rates, this valve guarantees a secure seal, reducing leaks and maximizing operational efficiency. Its bottom-entry design streamlines both maintenance and installation processes, making it ideal for a wide range of industrial applications. At Sichuan Yining Machinery Equipment Co., Ltd., we prioritize the needs of our B2B partners by providing tailored solutions. Crafted from durable materials and featuring robust construction, our valves are built to withstand demanding environments, ensuring peace of mind for users. Choosing the Best Bottom Entry Ball Valve is an investment in consistency and dependability, crucial for the success of any project. Partner with us to enhance your operations with high-quality equipment that meets industry standards and fulfills your expectations.Methods To Best Bottom Entry Ball Valve Service Guarantees Peak Performance

When it comes to ensuring the optimal performance of bottom entry ball valves, regular maintenance and servicing are pivotal. A well-maintained valve not only enhances operational efficiency but also significantly reduces the risk of unexpected failures. To achieve peak performance, it is essential to adopt a methodical approach to servicing these critical components. Routine checks should include inspecting the valve body for corrosion, ensuring the seals and seats are secure, and lubricating moving parts as per manufacturer specifications. Additionally, periodic testing for leaks and valve functionality helps in identifying potential issues before they escalate.

An integral aspect of valve service is the involvement of a skilled technical team. Their rich theoretical knowledge and practical experience enable them to implement effective maintenance strategies tailored to specific operational contexts. This expertise allows for deeper insights into the performance metrics of bottom entry ball valves, providing procurement professionals with the confidence that these parts will perform reliably over time. Proper training for operational staff on valve handling and maintenance techniques can further bolster performance and longevity.

In summary, investing in a comprehensive service regime for bottom entry ball valves is a crucial strategy for global procurement professionals aiming to guarantee peak performance in their operations. With a focus on preventive maintenance and leveraging technical expertise, companies can mitigate risks, enhance reliability, and ultimately secure a competitive edge in their respective industries.

Methods To Best Bottom Entry Ball Valve Service Guarantees Peak Performance

| Method | Description | Expected Outcome | Frequency |

|---|---|---|---|

| Regular Maintenance | Scheduled inspections and cleaning of the valve | Enhanced reliability and reduced risk of failures | Quarterly |

| Leak Testing | Conducting pressure tests to check for leaks | Prevention of fluid loss and environmental hazards | Annually |

| Replacement of Seals | Updating seals to ensure tight closure | Improved sealing performance and prolonging valve life | Every 2 years |

| Operational Training | Training operators on proper valve handling | Reduced operation errors and enhanced safety | As needed |

| Performance Monitoring | Using sensors to track valve performance | Immediate response to performance issues | Continuous |

The Clear Choice of Best Bottom Entry Ball Valve Pioneers in the Field Custom Solutions,

C

Chloe Scott

Highly recommend! This product truly delivers, and the customer service was remarkable.

23

June

2025

N

Nora Carter

Thrilled with the quality of this item! Customer care was attentive and informative.

24

May

2025

A

Alexander King

Pleased with the quality! The after-sales service was not only efficient but very approachable.

25

June

2025

E

Evelyn Brown

Top-notch quality! The support team was thorough and very helpful.

23

June

2025

D

Daisy Taylor

Incredibly high quality! The customer service team stood out for their care and expertise.

05

June

2025

A

Anastasia Hall

Thrilled with my purchase! The dedication shown by their service team made it all worthwhile.

13

May

2025