Ball Valve Stem Replacement Solutions from Leading ODM Manufacturers & Factories

At Sichuan Yining Machinery Equipment Co., Ltd., we provide reliable Ball Valve Stem Replacement solutions tailored for various manufacturers. Our OEM products are manufactured in a state-of-the-art facility, ensuring exceptional durability and performance. We recognize the critical role that precision and quality play in your operations, which is why our ball valve components are designed to meet the highest standards. Whether serving large manufacturers or smaller enterprises, our diverse range of ball valve components is crafted to suit your specific needs. Committed to customer satisfaction, we guarantee timely delivery and competitive pricing for our B2B partners. Partner with us to keep your machinery operating efficiently and effectively. Contact us today to learn more about our offerings.The Ultimate Guide to Ball Valve Stem Replacement Now Trending For the Current Year

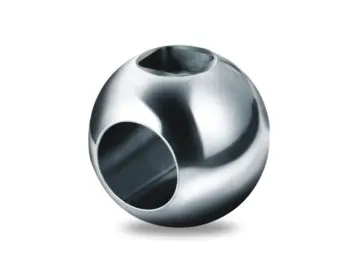

Ball valves are unique fixtures in fluid control systems, with their stem components playing a crucial role in ensuring leak-proof operation and efficient flow regulation. As industries evolve, the demand for reliable and durable valve solutions has surged, making stem replacement an essential topic for maintenance and procurement professionals. This comprehensive guide outlines the key considerations and steps for effective ball valve stem replacement, ensuring longevity and optimal performance in various applications.

Understanding the types of ball valves is the first step. There are floating, trunnion-mounted, and full-port variants, each with specific stem designs and configuration needs. The selection of the right materials for replacement stems—such as stainless steel for corrosion resistance or durable plastics for lightweight applications—is crucial in meeting performance requirements and industry standards. Additionally, familiarity with manufacturer specifications and compatibility will streamline the replacement process, reducing downtime and operational risks.

Before initiating the replacement process, proper preparation is vital. Ensure the system is depressurized, isolate the valve, and follow all safety protocols. Use appropriate tools and follow best practices to avoid damaging the valve body or other components during stem extraction and installation. A well-executed stem replacement not only enhances the functionality of the valve but also contributes to the overall efficiency of fluid systems. Timely maintenance and proactive replacement can lead to reduced operational costs and increased reliability in high-stakes environments.

The Ultimate Guide to Ball Valve Stem Replacement Now Trending For the Current Year

| Valve Type | Material | Stem Replacement Difficulty | Average Cost ($) | Replacement Frequency (Years) |

|---|---|---|---|---|

| Full Port Ball Valve | Stainless Steel | Medium | 150 | 5-10 |

| Reduced Port Ball Valve | PVC | Easy | 50 | 3-5 |

| Trunnion Mounted Ball Valve | Carbon Steel | Hard | 300 | 7-12 |

| Floating Ball Valve | Brass | Medium | 75 | 5-8 |

How To Ball Valve Stem Replacement Guarantees Peak Performance Supplier

D

Daniel Walker

Quality check passed! The support team was professional and resolved my queries with genuine care.

13

May

2025

M

Mia Allen

Simply top-notch! The product quality is matched only by the exceptional customer care.

18

May

2025

H

Harper Nelson

The attention to detail in the product is excellent. The support from the team has been stellar.

31

May

2025

S

Sophie Lee

Absolutely an amazing product! The after-sales team was knowledgeable and responsive.

21

June

2025

R

Ryan Lewis

Quality product that performs beautifully! Customer service was outstanding.

02

June

2025

N

Nora Adams

Delightful experience! Great product quality and equally great customer service.

05

June

2025