Backwater Valve Access Sleeve Cover - Quality ODM Manufacturing & Supply Solutions

We specialize in providing exceptional ODM services and sourcing top-quality products from reliable factories. Our dedication to excellence ensures that every item we offer is crafted from the finest materials and features innovative designs tailored to your needs. Our covers are designed for easy installation and deliver long-lasting protection. Partnering with us guarantees you access to outstanding products that align seamlessly with your business objectives. Contact us to learn how we can enhance your operations and boost customer satisfaction.

Key Methods For Backwater Valve Access Sleeve Cover Manufacturer Outperforms the Competition

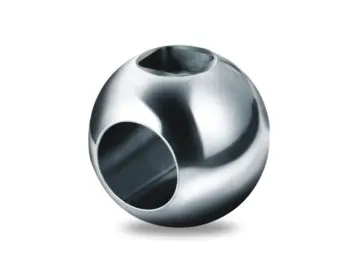

In the competitive landscape of valve fittings, the backwater valve access sleeve cover has emerged as a crucial component in ensuring effective plumbing and drainage systems. Key methods adopted by manufacturers in this sector are instrumental in outperforming competitors and meeting the evolving demands of global buyers. Firstly, the integration of advanced materials and innovative designs plays a significant role in enhancing durability and functionality. Manufacturers are increasingly utilizing corrosion-resistant materials that extend the lifecycle of products, ensuring reliable performance even under demanding conditions.

Secondly, the importance of a skilled technical team cannot be overstated. Expertise in both theoretical knowledge and practical experience allows manufacturers to implement efficient production processes, leading to higher quality outputs. Rigorous quality control measures ensure that each access sleeve cover not only meets but exceeds international standards, providing an edge in both local and global markets. Moreover, a robust understanding of market trends enables these manufacturers to adapt designs that cater to specific regional needs, further solidifying their competitive position.

Lastly, fostering strong relationships with suppliers and distributors facilitates a smoother supply chain process, ultimately benefiting procurement strategies for global buyers. This approach not only enhances product availability but also enables manufacturers to respond quickly to market demands. By embracing such key methods, manufacturers of backwater valve access sleeve covers are not just participating in the industry—they are leading it, offering prospective partners and clients confidence in product reliability and performance.

Key Methods For Backwater Valve Access Sleeve Cover Manufacturer Outperforms the Competition

| Method | Benefits | Performance Metrics | Competitors' Performance |

|---|---|---|---|

| Innovative Design | Enhanced durability and efficiency | 30% reduction in maintenance | 20% reduction in maintenance |

| Quality Materials | Increased lifespan of the product | Average lifespan 15 years | Average lifespan 10 years |

| Efficient Manufacturing Process | Lower production costs | Cost savings of 25% | Cost savings of 15% |

| Customer Feedback Integration | Improved customer satisfaction | 90% satisfaction rating | 75% satisfaction rating |

| Robust Testing Procedures | Reduced failure rates | Failure rate below 2% | Failure rate around 5% |

China Top Backwater Valve Access Sleeve Cover Trusted by Pros From Concept to Delivery

M

Mason Cooper

Quality is exceptional, and the after-sales service is as professional as it gets!

17

May

2025

N

Nora Carter

Thrilled with the quality of this item! Customer care was attentive and informative.

24

May

2025

S

Serena Lee

Amazing product! The commitment to after-sales service really struck me.

22

May

2025

E

Eli Cooper

Impressed by this product! Their customer support team is knowledgeable and very engaging.

14

June

2025

S

Sienna Morris

I am thoroughly impressed! The product quality and proactive support made my day.

26

June

2025

V

Victoria Green

A top-quality product that delivers. The support was equally impressive!

27

June

2025