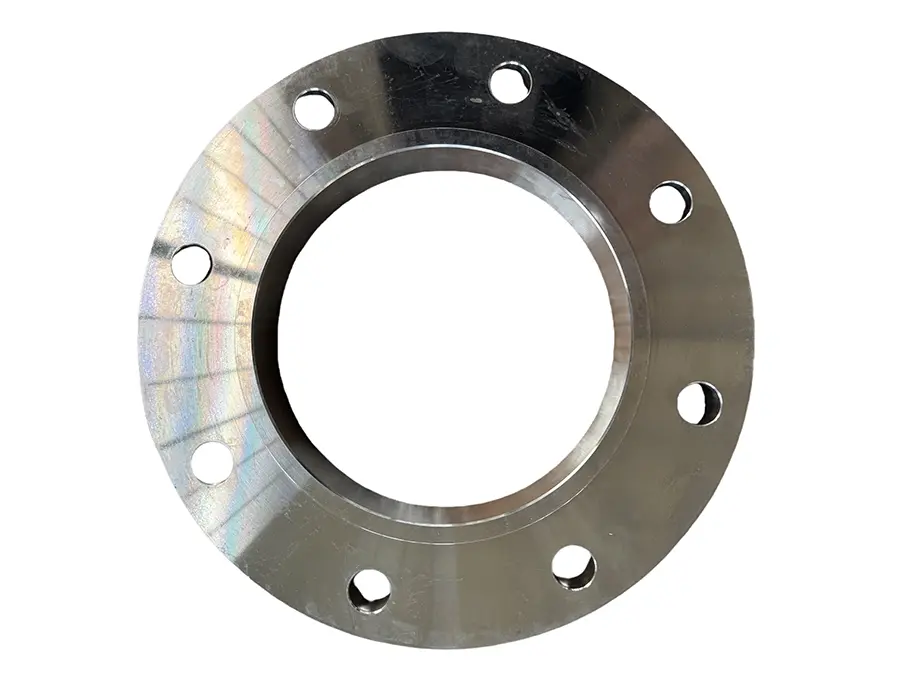

316L Stainless Steel Valve Transition Plate

-

Material & Performance

316L Stainless Steel Valve Transition Plate – Industrial Mounting Interface for Actuator AdaptationThis valve transition plate, machined from solid 316L stainless steel, is engineered to provide a stable and reliable connection between valve bodies and their corresponding actuators. It is especially useful when actuator mounting patterns do not match the top flange of the valve. The plate serves as an intermediate adapter, minimizing misalignment, mechanical stress, and installation inconsistencies.The flat plate structure is precision-cut using CNC equipment to ensure dimensional accuracy. All mounting holes are chamfered and clean, accommodating electric, pneumatic, and manual actuators. The material selection of 316L stainless steel ensures corrosion resistance in environments such as chemical processing, water treatment, and marine installations.Commonly used in systems incorporating flush tank ball valves, cold water tank ball valves, and cistern float valves, this plate helps achieve consistent performance and ease of maintenance. OEMs and automation engineers favor this solution when retrofitting, upgrading, or integrating non-standard valve-actuator combinations.

-

Key Features

-

Why Engineers Choose This

-

FAQ